5 Cutting Technologies Driving the Move Toward Cleaner, Smarter Manufacturing

Published: 2025-09-16

Today's factories are being squeezed to do more with less. Energy prices go up, environmental regulations rise, and customer demands for quality goods allow no margin for error. Outdated cutting techniques tend to yield scrap material, excess rework, and longer turnaround.

These are the problems that nibble away at profit and strain supply chains. They are not minor problems for most manufacturers. These rather play a part in whether you lose or win a contract.

The argument for change is proven in numbers. As reported by the International Energy Agency, industry accounts for nearly 20% of world carbon emissions, and wasteful production techniques are still one of the biggest culprits.

So, businesses that hold on to outdated cutting techniques are at risk. They can be overshadowed by their rivals, who use a cleaner technology.

This shift isn't just about reducing costs. It's about building strong, sustainable operations that can expand while meeting both customer and regulatory expectations.

The following five technologies are revolutionizing industries' understanding of cutting. Therefore, making manufacturing smarter, cleaner, and more profitable.

Keep reading to find out more.

1. Waterjet Cutting: Cold Precision at Industrial Scale

Waterjet cutting has become a game-changer in industries where accuracy and material integrity matter. Waterjets use ultra-high-pressure water, sometimes mixed with abrasives, to slice through everything from aerospace-grade titanium to delicate glass.

In simple words, it does not rely on heat. Therefore, the result is clean, precise edges without the distortions that heat-based methods often leave behind.

Think about an aircraft manufacturer shaping turbine components. Even slight thermal stress could compromise safety. Waterjet cutting eliminates that risk by keeping materials cold, ensuring critical parts maintain their full structural strength. Or consider a design studio working with glass. The panels cut using waterjets come out ready to install. Also, the experts do not have to deal with the cracked edges polishing process.

Why it works so well:

-

No heat-affected zones: Materials retain integrity and performance.

-

Broad material compatibility: From foam to hardened steel, versatility is unmatched.

-

Cleaner finish: Less secondary processing saves time and energy.

The business case is compelling. The global waterjet cutting machine market is growing at a rapid rate. The rise highlights how industries are prioritizing “cold cutting” to meet tighter tolerances and sustainability goals.

For companies investing in the future, waterjet systems are readily available through specialized manufacturers who engineer solutions specifically for industrial needs. Choosing the right partner ensures not just precision today, but scalable reliability as production grows.

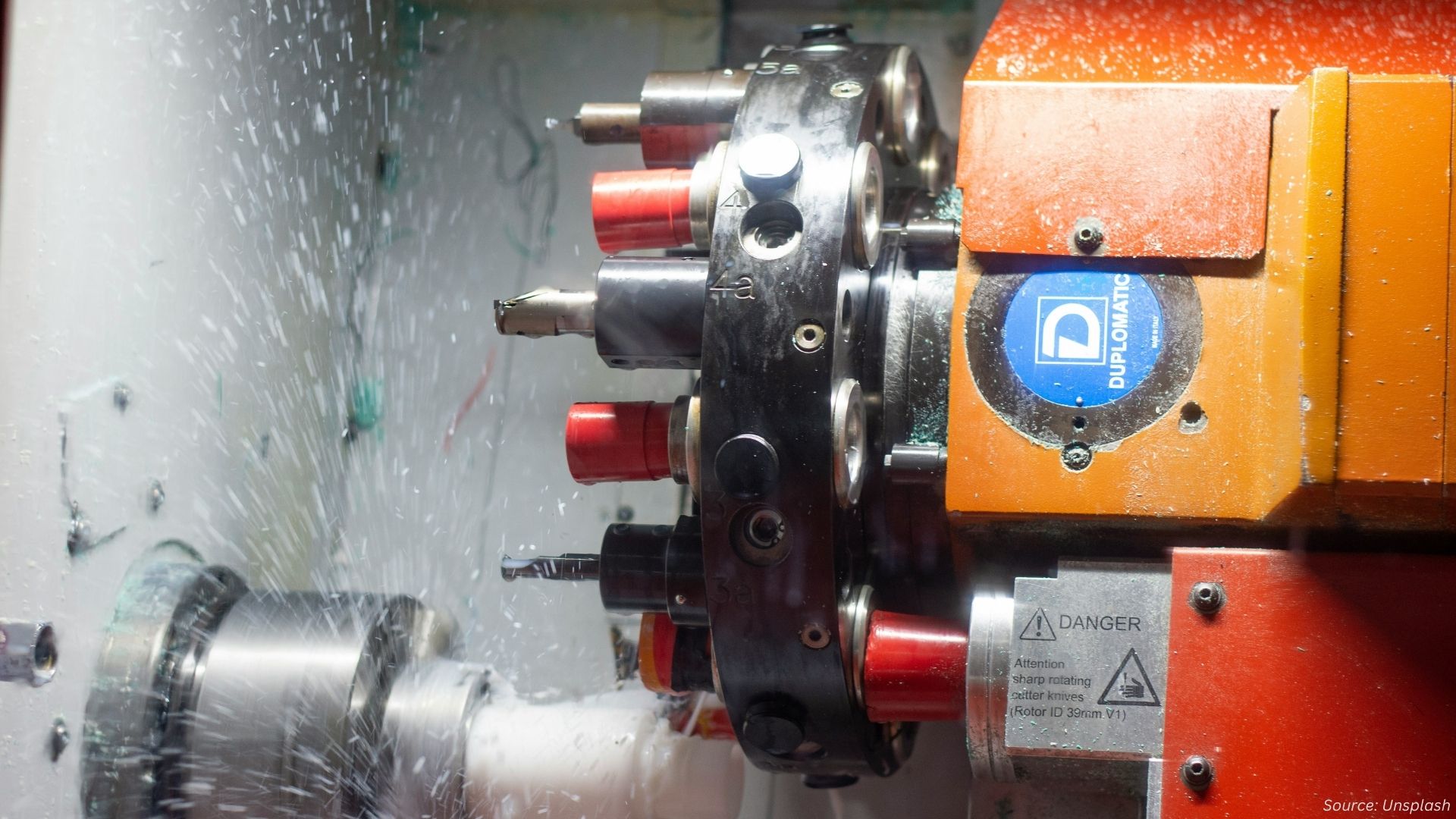

2. CNC Routers: Digital Workhorses for Flexible Production

Though waterjet possesses the edge when it comes to versatility, CNC routers enjoy the benefit of flexibility. Essentially, CNC routers convert computer designs into real-life products with unprecedented repeatability. Under the direction of digital files, the machine's multi-axis spindles cut wood, plastics, composites, and metals into shapes with precision.

They are therefore invaluable in applications where design complexity and quick turnaround are critical. A woodworker, for instance, can change from trimming custom cabinetry in the morning to shaping complex decorative overlays in the afternoon. In sign making, routers will cut out detailed branding components that could never be replicated with hand tools.

-

Computer precision: Each CAD nuance shows up on the finished product.

-

Efficiency at scale: Nesting layouts saves scrap but allows for repeat runs.

-

Ease of adoption: Routers come with straightforward controls, so non-engineers can use them.

The market mirrors this growth. Additional research predicts even more growth, fueled by consumer and industrial demand for custom, short-run products.

What makes CNC routers so attractive is the way they bridge craft and automation. Automatic tool changes, small footprint sizes, and sophisticated software make it possible for large manufacturers to add capacity without a great deal of overhead, as well as for small shops.

Small and medium-sized enterprises, including startups against big players, can leverage CNC routers as a means of providing professional-grade quality at a lower expense. It is something that directly affects competitiveness.

3. Laser Cutting: Speed Meets Intricacy

Laser cutting combines speed, accuracy, and flexibility. Employing focused beams of light, it is capable of vaporizing material with micrometer precision. To manufacturers, that means quicker throughput and higher detail than conventional cutting provides.

Consider electronics production. Components and circuit housings need tight tolerances, allowing no margin for error. A laser can slice quickly through thin plastics or metals with clean edges. Or in the automotive sector, decorative panels frequently call for fancy designs—something that lasers are great at creating in high volume.

Benefits that stand out:

-

Tight kerfs: Narrow cuts maximize material usage.

-

Minimal finishing: Edges often need little to no polishing.

-

Adaptability: Fiber lasers handle reflective surfaces like stainless steel with ease.

When integrated with robotics, laser systems go beyond precision—they scale. Automated feeders and handlers keep production lines moving without manual intervention. This combination is helping factories achieve up to 50% reductions in bottlenecks, according to industry case studies.

Laser cutting isn’t just about detail; it’s about leaner, faster workflows. For companies competing in global markets, that speed can be the difference between winning contracts or missing them.

4. Plasma Cutting: Rugged Strength with Modern Upgrades

Plasma cutting has never been about precision. By ionizing gas into plasma, such systems produce the heat sufficient to cut through heavy steel and other dense metals. While waterjets and lasers make precision their goal, plasma makes volume its target.

But today's plasma is no longer the crude-edged tool of old. Today's machines employ:

-

Automatic height control to ensure uniform cuts.

-

Pilot arc technology to cut rusted or coated metals.

-

Robotic arms to provide repeatable performance at scale.

For applications such as shipbuilding, mining machinery, or construction equipment, plasma cutting provides harsh-duty reliability. Steel plates an inch thick can be cut rapidly, with enhanced edge quality appropriate for welding or assembly. The result is quicker fabrication and reduced finishing cost.

5. Diamond Wire Cutting: Precision for Fragile and Hard Materials

Some materials simply don’t respond well to heat or vibration. For them, diamond wire cutting provides a solution. The process uses a thin wire coated with diamond grit, which slices steadily through stone, ceramics, or thick glass blocks.

The biggest advantage? Low vibration. Traditional saws often chip or crack delicate surfaces. Diamond wire, by contrast, produces smooth edges with minimal risk of damage. This makes it popular in both construction and specialty industries.

Consider marble quarries, where slabs worth thousands of dollars must be extracted without fracture. Or labs working with brittle ceramics, where even tiny cracks could ruin results. Diamond wire delivers cuts that preserve both appearance and structural integrity.

Why manufacturers value it:

-

Smooth edges reduce waste, ensuring more usable product.

-

Lower stress on materials means fewer rejected parts.

-

Flexibility to work across hard and fragile substrates.

Diamond wire may not match lasers in speed or plasma in brute strength, but it fills a critical role: making the uncuttable cuttable. For businesses working with premium or fragile materials, it ensures both sustainability and profitability.

Why These Technologies Matter Together

Individually, each cutting technology addresses a very distinct challenge. Together, however, they form a smarter, more sustainable manufacturing environment — one that harmonizes output, material usage, precision, and cost containment.

Here's how they play off each other:

-

Waterjets cut sensitive or thermal-sensitive materials with minimal waste.

-

CNC routers provide unparalleled design freedom, particularly in wood, composites, and plastics.

-

Laser cutters provide great accuracy with stunning speed — perfect for intricate or repetitive work.

-

Plasma cutting tackles heavy metals and bulk requirements without interrupting production.

-

Diamond wire cutting is masterful at molding brittle or precious materials with minimal waste.

These technologies collectively allow manufacturers to address an incredibly diverse set of materials and applications. They do not have to sacrifice efficiency, quality, or environmental sustainability. It is not merely a question of having the tech; rather, it is about having one, at the right moment, for the right purpose.

This transition is more than technological. It is a change in mindset. Businesses implementing these technologies are gearing up to meet increasing customer demands, comply with new environmental standards, and minimize overhead. In the competitive market of today, integrating tools such as these might be what sets agile, future-proof manufacturers apart from those who are struggling to catch up.

Conclusion

Today, what we manufacture is not just what we produce. Quality, efficiency, and sustainability are of equal importance now. That’s why the cutting-edge tech is changing and advancing so quickly. With cold, precision waterjets, brute force plasma, the flexibility of CNC routers, and the intricacy of diamond wire, manufacturers have more choices than ever to drive production into the future.

'Demand for the right cutting system is not only about investing in machinery - it’s about future-proofing production'. The result is less waste from cleaner processes, higher competitiveness from smarter automation, and new opportunities for design advances from precision tools. With normal markets change and the expectation for more, those behind the curve in adopting such will likely be laggards.

About the Author

Saloni is an experienced writer with over three years at Outreach Monks, creating content across diverse niches. She combines research skills and clear writing to deliver valuable industry insights, making complex topics easier for readers to understand. Outside of work, Saloni enjoys reading and dancing. She also loves exploring new restaurants and spending time with friends and family.

Saloni is an experienced writer with over three years at Outreach Monks, creating content across diverse niches. She combines research skills and clear writing to deliver valuable industry insights, making complex topics easier for readers to understand. Outside of work, Saloni enjoys reading and dancing. She also loves exploring new restaurants and spending time with friends and family.

About the Reviewer

Sanyukta Deb is a seasoned Content Writer and Team Leader in Digital Marketing, known for her expertise in crafting online visibility strategies and navigating the dynamic digital landscape. With a flair for developing data-driven campaigns and producing compelling, audience-focused content, she helps brands elevate their presence and deepen user engagement. Beyond her professional endeavors, Sanyukta finds inspiration in creative projects and design pursuits.

Sanyukta Deb is a seasoned Content Writer and Team Leader in Digital Marketing, known for her expertise in crafting online visibility strategies and navigating the dynamic digital landscape. With a flair for developing data-driven campaigns and producing compelling, audience-focused content, she helps brands elevate their presence and deepen user engagement. Beyond her professional endeavors, Sanyukta finds inspiration in creative projects and design pursuits.

Add Comment