How Smart Cutting Tech Can Give Small Manufacturers a Big Advantage

Published: 2025-09-16

Not long ago, precision cutting tools were a luxury only large manufacturers could afford. Today, the script has flipped. As smart manufacturing reshapes the industrial landscape, small workshops are finding new ways to compete with the big players—without needing a massive budget or an army of engineers. One of the most accessible and transformative tools driving this shift? Waterjet cutting. With advanced solutions like TECHNI Waterjet systems, even small shops can achieve the same level of accuracy and efficiency once reserved for large-scale production.

Agile, efficient, and impressively versatile, waterjet technology has become the secret weapon of lean fabrication teams looking to punch above their weight. Whether it’s a custom metal bracket or a one-off prototype made of stone, the precision and flexibility of this method are leveling the playing field for small operations.

What Is Precision Waterjet Cutting and Why Should Small Shops Care?

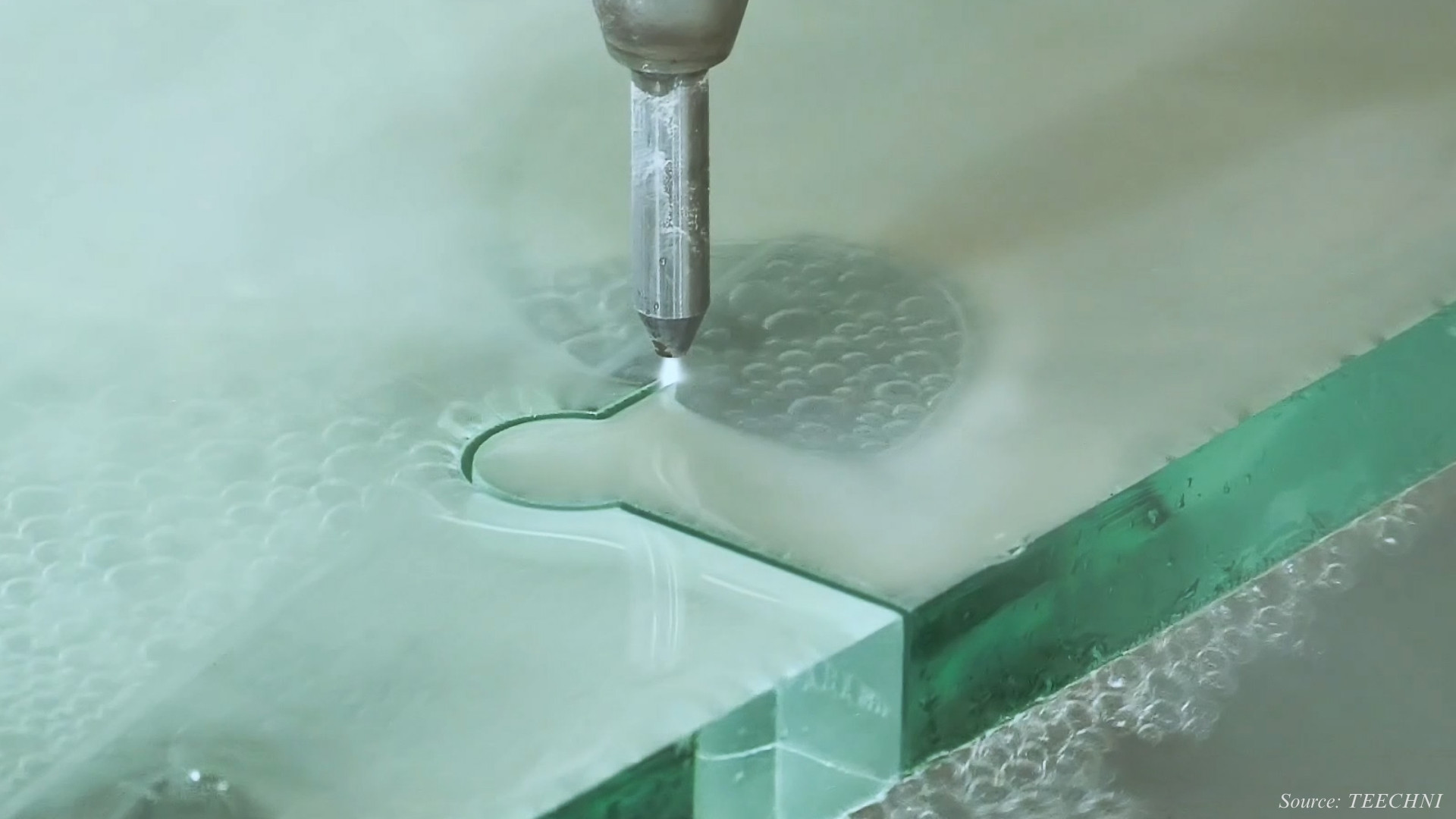

Waterjet cutting is a cold-cutting process that uses a high-pressure stream of water—often mixed with abrasive particles—to slice through a wide range of materials with remarkable accuracy.

It differs sharply from traditional tools like bandsaws, plasma cutters, or even lasers. While saws struggle with complex contours, plasma often leaves rough edges and heat-affected zones. Even laser systems have limitations with thick or reflective materials. Waterjet, by contrast, cuts cleanly, leaves no heat distortion, and handles everything from soft foam to hardened steel.

This makes it ideal for short-run production, intricate custom jobs, and delicate materials. If you're building prototypes or offering contract cutting services, waterjet gives you precision without compromise.

How Does Waterjet Cutting Actually Work?

Waterjet cutting may look like magic, but the process is based on a few powerful physical principles.

Here’s how it works:

-

Pressurizing water (up to 60,000–90,000 psi) using a hydraulic intensifier pump

-

Adding abrasive (typically garnet) to the water stream to enhance cutting power

-

Converting pressurized stream into a focused cutting jet through a small orifice

-

Moving via CNC controller to trace the programmed cutting path with high precision

There are two primary types of waterjet systems:

-

Pure waterjet uses only water and is ideal for soft materials like foam, rubber, and food products.

-

Abrasive waterjet, which includes particles like garnet, is used for harder materials such as metal, glass, and stone.

What Types of Waterjet Machines Are Available Today?

The configuration you choose depends on your shop size, part complexity, and budget. Let’s look at the main types:

3-Axis Waterjet Machines

These systems move in X, Y, and Z directions, suitable for 2D shapes and standard flat cutting.

-

Pros: Simpler, lower cost, ideal for sheet materials

-

Cons: Limited ability for angled or contoured cuts

5-Axis Waterjet Machines

With rotational axes, these can cut bevels, tapers, and 3D contours.

-

Pros: Versatile for complex parts

-

Cons: Higher cost, requires more advanced programming

Mini/Tabletop Waterjets

Compact units designed for small workshops, sign makers, and prototypers.

-

Pros: Lower footprint, easier setup, affordable entry point

-

Cons: Smaller cutting envelope, slower cutting speeds

Gantry-Style Industrial Waterjets

Large-format machines with open tables, built for high throughput and full sheets.

-

Pros: Scalable production, handles large parts

-

Cons: High upfront cost, requires more space and utilities

What Are the Key Parts of a Waterjet Cutting System?

Each waterjet setup relies on a combination of components working in unison:

-

High-pressure pump – Delivers the water at cutting pressure

-

Cutting head/nozzle – Focuses the stream into a precise jet

-

Abrasive hopper – Feeds garnet into the waterjet mix

-

CNC controller – Interprets design files and motion control. You can learn what is motion control to better understand how machines follow precise movement commands.

-

Slats/table – Supports the workpiece and absorbs splash

-

Catch tank – Collects water and spent abrasive

-

Water filtration/recycling system – Reuses water and reduces waste

What Parameters Matter Most in Waterjet Cutting?

Performance and cut quality depend on several controllable parameters:

-

Pressure (psi) – Higher pressure = faster, cleaner cuts

-

Nozzle diameter – Smaller nozzles = finer detail

-

Cutting speed – Measured in inches or mm per minute

-

Material type and thickness – Determines pressure and abrasive needs

-

Abrasive flow rate – Impacts kerf and cut edge quality

-

Stand-off distance – Gap between nozzle and workpiece

-

Tolerance and kerf width – Affects part accuracy and fit

What Are the Typical Tolerances in Waterjet Cutting?

-

Thin materials: ±0.003" to ±0.005" (±0.08 to ±0.13 mm)

-

Medium thickness: ±0.005" to ±0.01" (±0.13 to ±0.25 mm)

-

Thick plates (2”+): ±0.015" to ±0.030" (±0.38 to ±0.76 mm)

What Materials and Thicknesses Can Waterjet Cut?

From ductile metals to brittle glass, the material range is vast:

-

Mild Steel: Up to 6" (150 mm)

-

Aluminum: Up to 8" (200 mm)

-

Granite: Up to 4" (100 mm)

-

Glass: Up to 2" (50 mm), depending on type

What Types of Materials Are Ideal for Waterjet Cutting?

Waterjet systems are prized for their ability to cut a broad array of materials without introducing heat stress. Here’s how different materials respond:

Mild Steel (Carbon Steel)

-

Tough and dense, but cuts cleanly with abrasive waterjets

-

Great for brackets, frames, and general fabrication

Stainless Steel

-

Resistant to corrosion and oxidation

-

Maintains finish due to cold cutting — ideal for sanitary or aesthetic parts

Aluminum

-

Lightweight and highly machinable

-

Waterjet avoids edge hardening, making post-processing easier

Brass and Copper

-

Soft metals with excellent thermal conductivity

-

Waterjet preserves material integrity and fine details

Titanium and Alloys

-

High strength-to-weight ratio

-

Waterjet is preferred to avoid thermal deformation

Glass, Ceramics, and Stone

-

Fragile and heat-sensitive

-

Requires precise control and support during cutting

Plastics and Composites

-

Cuts cleanly without melting or charring

-

Useful for gaskets, enclosures, or composite panels

Rubber and Foam (Pure Waterjet Only)

-

Soft, flexible materials

-

Pure waterjet avoids contamination and excessive wear

What Materials Should Be Avoided?

While versatile, waterjets aren’t perfect for everything. Materials to avoid include:

-

Tempered glass (shatters)

-

Laminated composites (may delaminate)

-

Very thin layered foils (can flutter or warp)

-

Brittle electronics or circuit boards

What Are the Advantages of Waterjet Cutting for Small Businesses?

For lean operations, a water jet cutter offers key benefits:

-

Cold cutting (no heat-affected zones)

-

Handles almost any material

-

Excellent edge finish (less secondary work)

-

Minimal kerf and high precision

-

Scalable for both prototypes and full runs

-

No tooling required

-

Easy nesting = minimal material waste

-

Compatible with low-volume, high-mix jobs

Which Industries Are Using Waterjet Cutting to Stay Competitive?

From one-off jobs to batch production, use cases are multiplying:

-

Custom Fabrication Shops – metal brackets, panels, custom parts

-

Signage and Display – acrylic letters, metal signs, stencils

-

Automotive and Motorsports – gaskets, brackets, aluminum parts

-

Aerospace – composites, titanium, ceramic parts

-

Architecture and Interior Design – decorative panels, stone inlays

-

Tool and Die Shops – precision cutting of blanks

-

Prototyping Startups – one-off parts with quick turnaround

What Should You Consider Before Investing in a Waterjet Cutter?

It’s a powerful tool—but not plug-and-play. Consider:

-

Initial equipment cost vs. outsourcing

-

Floor space and utility requirements

-

Operator training and experience

-

Materials you plan to cut

-

Maintenance and consumables

-

Water recycling options

-

Integration with CAD/CAM workflow

Avoid common mistakes like underestimating abrasive costs or skipping routine maintenance.

How Do You Cut Parts with a Waterjet Step-by-Step?

The workflow is streamlined but requires discipline:

-

Design in CAD

-

Convert to machine code (CAM)

-

Material prep and secure on table

-

Set cutting parameters

-

Run test cut

-

Execute full cut

-

Inspect and finish as needed

What Are the Key Design Considerations for Waterjet Cutting?

-

Minimize narrow slots and tight inside corners

-

Watch kerf allowance

-

Avoid unsupported interior geometry

-

Use tabs or bridges for stencil-style parts

-

Add lead-ins and lead-outs to improve edge quality

What Preparations Should Be Made Before Each Cut?

-

Clean work surface

-

Confirm material thickness and type

-

Check pump pressure and abrasive level

-

Verify fixture and clamp setup

-

Run simulation if software allows

What Safety Tips Should Small Shops Follow with Waterjets?

-

Wear eye and ear protection

-

Shield abrasive and nozzle area

-

Watch high-pressure lines

-

Monitor water level in catch tank

-

Perform regular maintenance and checks

What are the Best Waterjet Cutting Machines for Small Businesses?

Key features to look for:

-

Compact footprint

-

Affordable maintenance

-

Reliable support/training

-

Compatible with standard CAD/CAM software

-

Strong pump and nozzle combo

-

Abrasive recycling option

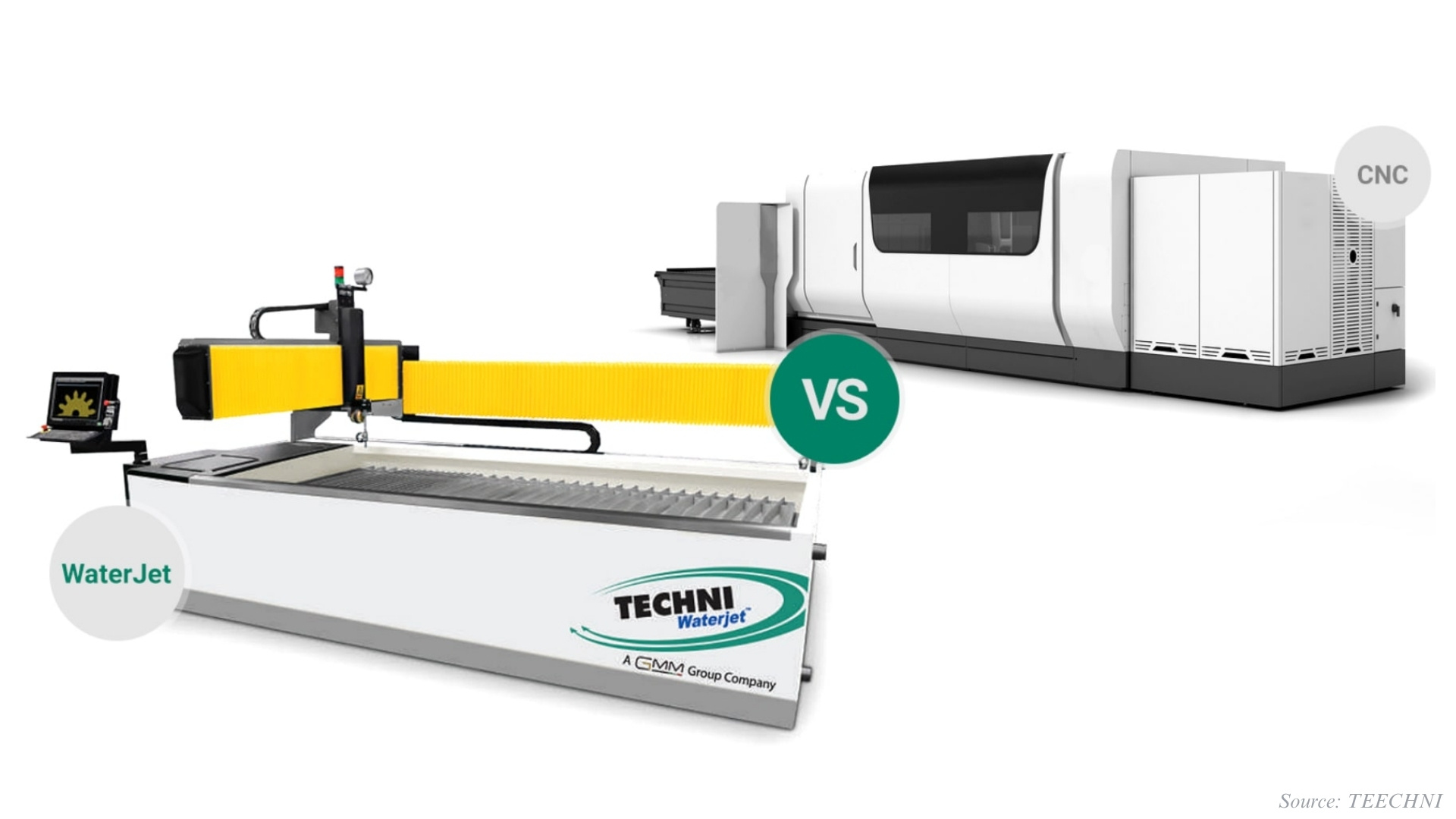

What Other Technologies Compete with Waterjet Cutting?

Alternatives exist, but none are as universally flexible:

-

Laser Cutting – Fast and clean, but struggles with thick or reflective materials

-

Plasma Cutting – Good for thick steel, poor edge quality

-

Mechanical Cutting – Effective, but tool wear and limitations with hard materials

-

EDM – Ultra-precise, but slow and limited to conductive materials

Waterjet bridges many of these gaps with material agnosticism and clean edges.

Conclusion

In an age of smart manufacturing, small workshops don’t need to stay small-minded. Waterjet cutting opens up a toolkit once reserved for massive operations—now scaled for lean budgets and flexible workflows. It’s not just about slicing materials. It’s about carving out a future where precision and versatility lead to real growth.

If you're looking for a tool that adapts as fast as your business evolves, this might just be your sharpest edge.

About the Author

Elia Guidorzi is the International Marketing Executive at Techni Waterjet, where he drives global brand growth and strategic communications for advanced waterjet cutting solutions

About the Reviewer

Joydeep Dey is an SEO Executive, Content Writer, and AI enthusiast with over 2½ years of experience in digital marketing and artificial intelligence. He specializes in crafting smart SEO strategies, creating engaging content, and exploring AI-powered solutions that boost online visibility and audience engagement. Outside of work, you’ll often find Joydeep exploring new gadgets, binge-watching a good series, or just wandering around for fresh inspiration.

Joydeep Dey is an SEO Executive, Content Writer, and AI enthusiast with over 2½ years of experience in digital marketing and artificial intelligence. He specializes in crafting smart SEO strategies, creating engaging content, and exploring AI-powered solutions that boost online visibility and audience engagement. Outside of work, you’ll often find Joydeep exploring new gadgets, binge-watching a good series, or just wandering around for fresh inspiration.

Add Comment