Electrolyzers Market: BASF & HIF Lead Green Hydrogen Push

Published: 2025-10-17

Lede

Two transformative projects — BASF’s 54-megawatt proton exchange membrane (PEM) electrolyzer in Germany and HIF Global’s large-scale deployment of Electric Hydrogen’s U.S.-manufactured systems in Texas — have emerged as landmark achievements shaping the global Electrolyzers Market.

These developments highlight a rapidly maturing hydrogen economy where technology innovation, industrial integration, and regional manufacturing are converging. As both Europe and the U.S. intensify efforts to meet net-zero commitments, electrolyzers are evolving from experimental prototypes to mission-critical infrastructure powering clean fuels, green chemicals, and decarbonized heavy industries.

Beyond the immediate technological achievements, these milestones signify a deeper shift: hydrogen is no longer a peripheral component of the clean energy ecosystem — it’s becoming the central pillar of industrial transformation and economic resilience.

1. BASF’s 54-Megawatt Green Hydrogen Facility: Integration at Industrial Scale

In a major step toward sustainable chemical manufacturing, BASF SE has commissioned Germany’s largest proton exchange membrane (PEM) electrolyzer at its Ludwigshafen site. Developed in partnership with Siemens Energy, the installation boasts a connected load of 54 megawatts, capable of producing up to 8,000 metric tons of hydrogen annually.

The project, known as Hy4Chem, marks a global first — directly embedding a large-scale water electrolyzer into an existing chemical production ecosystem. This integration allows green hydrogen to be used as both a feedstock for chemical synthesis and a regional mobility fuel. The hydrogen feeds into BASF’s Verbund network, supporting production of key compounds such as ammonia, methanol, and vitamins, while significantly reducing the facility’s dependence on natural gas.

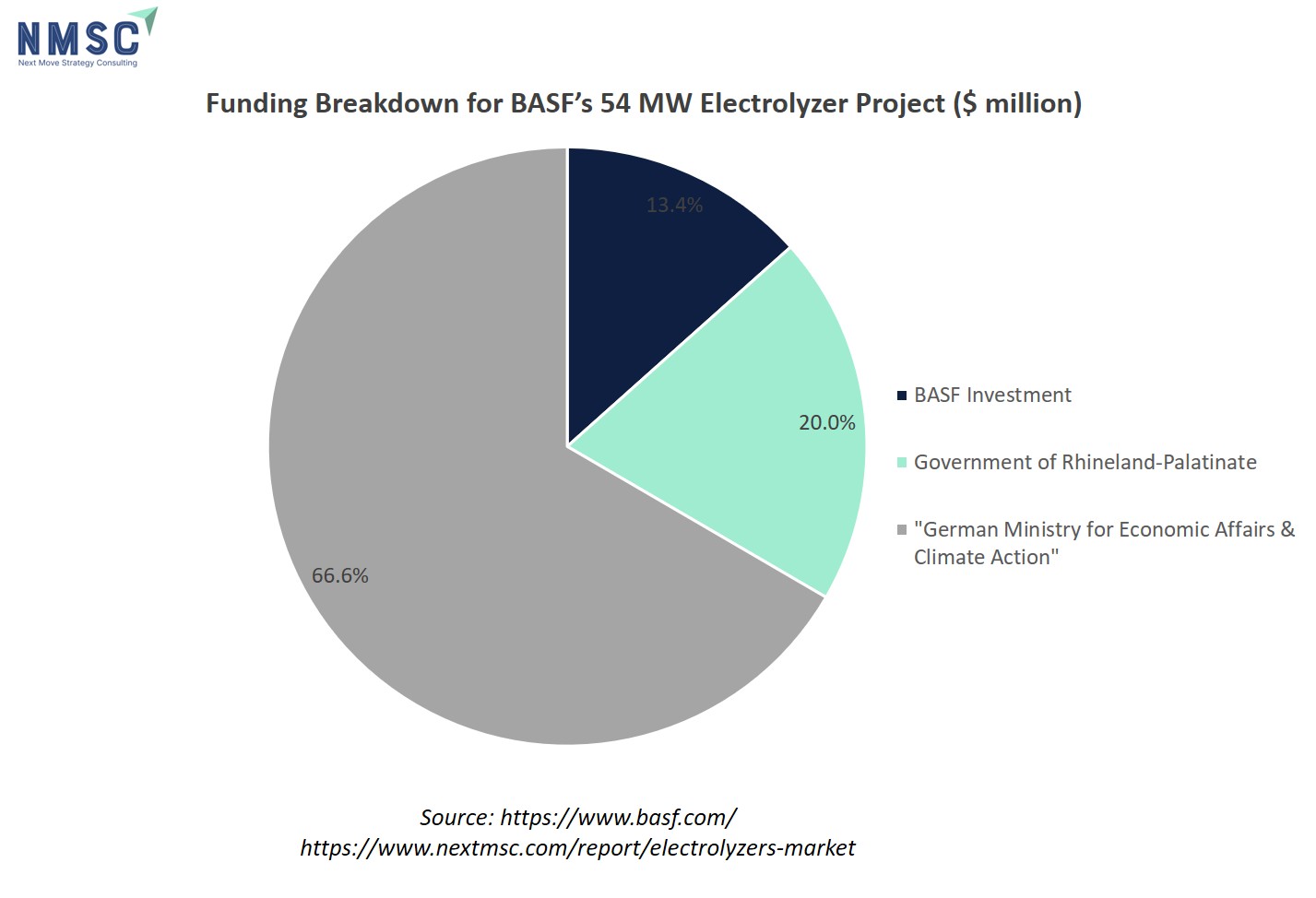

According to BASF, the electrolyzer could cut up to 72,000 metric tons of CO₂ emissions per year, advancing its long-term decarbonization targets. Funded with approximately €124.3 million in combined support from Germany’s federal and state governments — and an additional €25 million from BASF — the project exemplifies public-private collaboration at the forefront of the European hydrogen transition.

Government officials hailed the plant’s commissioning as a milestone in industrial climate action. Rhineland-Palatinate’s Minister for Climate Protection Katrin Eder praised BASF’s approach as “a model for how energy-intensive industries can transition to net-zero while remaining globally competitive.”

BASF, in collaboration with Siemens Energy, has commissioned a 54 MW water electrolyzer at its Ludwigshafen site — integrating hydrogen production directly into its chemical operations. The system, comprising 72 electrolysis stacks, can cut up to 72,000 metric tons of CO₂ emissions annually. Using renewable power, the hydrogen will serve as feedstock for BASF’s processes and support regional mobility in the Rhine-Neckar area. The €186.6 million Hy4Chem project received €124.3 million in federal support, €37.3 million from Rhineland-Palatinate, and €25 million from BASF’s own investment.

2. HIF Global and Electric Hydrogen: U.S. Manufacturing Takes the Lead

On the other side of the Atlantic, the United States is taking decisive steps toward establishing domestic dominance in hydrogen technology. HIF Global, a global leader in e-Fuels and synthetic energy solutions, announced that it has selected Electric Hydrogen (EH2) to provide electrolyzer systems for its Matagorda, Texas e-Fuels facility — a project that stands among the largest deployments of American-built electrolyzers to date.

Electric Hydrogen’s advanced PEM systems, designed in Devens, Massachusetts and manufactured across Texas, are engineered to deliver high output at the lowest total installed cost globally. The company’s design emphasizes modularity, scalability, and supply chain resilience, enabling rapid assembly and deployment in large-scale industrial applications.

The hydrogen generated at the Matagorda plant will be converted into e-Methanol, a synthetic fuel critical for decarbonizing hard-to-abate sectors such as aviation, shipping, and heavy transport.

HIF Global’s Executive Director Meg Gentle described the project as “a defining moment for U.S. clean-tech leadership,” emphasizing that American innovation and workforce capability are key to reducing dependence on imported clean energy technologies. EH2’s CEO Raffi Garabedian echoed the sentiment, calling the collaboration “proof that U.S.-built electrolyzer solutions can meet global performance standards at industrial scale.”

From a strategic perspective, this project repositions the United States as a manufacturing and innovation hub in the global Electrolyzers Market — a sector historically dominated by European and Asian suppliers. It also aligns with Washington’s broader policy framework encouraging reshoring of clean-tech manufacturing and leveraging the Inflation Reduction Act (IRA) incentives to spur domestic production capacity.

3. The Broader Market Shift: From Demonstration to Deployment

Both BASF’s and HIF Global’s initiatives underscore a critical inflection point in the Electrolyzers Market — a move from laboratory-scale demonstration to fully integrated industrial operations.

The increasing number of multi-megawatt projects signifies that electrolyzer technology has crossed a commercial viability threshold. What was once a research topic confined to pilot plants is now a pillar of corporate energy transition strategies.

Globally, demand for electrolyzers is being driven by three primary forces:

-

Industrial decarbonization goals among chemicals, steel, and heavy manufacturing sectors.

-

Renewable energy integration, leveraging hydrogen for storage and grid stability.

-

Policy-backed funding, especially in Europe, the U.S., and Asia-Pacific, targeting energy independence and carbon neutrality.

Key Players Shaping the Electrolyzers Market

Leading companies in the global electrolyzers industry include Nel Hydrogen, ITM Power Plc., Plug Power Inc., Siemens AG, Sunfire GmbH, Bloom Energy, Thyssenkrupp Nucera, Enapter, John Cockerill, McPhy Energy SA, Air Liquide S.A., 1s1 Energy, Air Products and Chemicals Inc., and Giner Inc., among others. These players are actively pursuing strategies such as acquisitions, partnerships, and technological collaborations to strengthen their market presence and sustain leadership in the rapidly expanding hydrogen economy.

4. Next Move Strategy Consulting – Opinion, Impact and Market Outlook

According to Next Move Strategy Consulting, the concurrent rise of large-scale projects like BASF’s Hy4Chem and HIF’s Texas facility signals a strategic consolidation phase within the Electrolyzers Market.

Their analysis identifies five dominant forces shaping the market’s next decade:

-

Scale-up and Manufacturing Consistency:

As multi-megawatt installations become the norm, consistent quality control and long-term stack reliability will separate early innovators from sustainable market leaders.

-

Regional Industrial Integration:

BASF’s embedded model shows that integrating electrolyzers within existing industrial ecosystems significantly enhances energy efficiency and cost recovery, especially when paired with renewable power sources.

-

Policy-Driven Acceleration:

The European Union’s Hydrogen Strategy, Germany’s IPCEI funding, and U.S. IRA incentives collectively form the strongest public funding wave in clean-tech history, setting the stage for mass adoption.

-

Technology Diversification:

The competition between PEM, alkaline, and solid oxide electrolyzers will intensify. PEM systems currently lead in flexibility and dynamic operation, while alkaline remains cost-effective for large installations.

-

Sustainability as Market Currency:

Electrolyzer manufacturers that can document low lifecycle emissions and recyclable system components will secure a stronger foothold in the procurement preferences of climate-focused industries.

Next Move Strategy Consulting anticipates a compound annual growth rate (CAGR) exceeding 20% from 2025 to 2032, supported by both private capital influx and cross-border hydrogen trade initiatives.

5. Practical Recommendations for Stakeholders

-

Manufacturers should invest in automation, stack durability testing, and localized supply chains to meet cost and delivery benchmarks.

-

Energy firms must integrate electrolyzers with renewable assets — particularly solar and wind — to stabilize operations and maximize energy utilization rates.

-

Investors should prioritize companies with proven scalability, domestic manufacturing capacity, and long-term service models.

-

Policy makers should continue to harmonize standards, fund demonstration plants, and support export infrastructure for hydrogen and e-Fuels.

-

Industrial end-users should explore long-term offtake agreements to secure early access to low-carbon hydrogen at competitive rates.

Conclusion: A Defining Moment for the Electrolyzers Market

The inauguration of BASF’s 54 MW electrolyzer and HIF Global’s selection of Electric Hydrogen technology represent more than isolated progress — they define a global pivot toward industrial-scale hydrogen production.

The Electrolyzers Market is evolving from a technology race into a strategic pillar of energy and industrial policy. As countries compete for leadership in hydrogen technology, the winners will be those who can integrate innovation with manufacturability, policy support, and lifecycle sustainability.

For both Europe and the U.S., these milestones symbolize the start of a new industrial era — one where green hydrogen is not merely an alternative fuel but the foundation of a decarbonized economy capable of sustaining growth, competitiveness, and environmental responsibility.

About Next Move Strategy Consulting

Next Move Strategy Consulting is a premier market research and management consulting firm that has been committed to provide strategically analysed well documented latest research reports to its clients. The research industry is flooded with many firms to choose from, what makes Next Move different from the rest is its top-quality research and the obsession of turning data into knowledge by dissecting every bit of it and providing fact-based research recommendation that is supported by information collected from over 500 million websites, paid databases, industry journals and one on one consultations with industry experts across a diverse range of industry sectors. The high-quality customized research reports with actionable insights and excellent end-to-end customer service help our clients to take critical business decisions that enables them to move beyond time and have competitive edge in the industry.

We have been servicing over 1000 customers globally that includes 90% of the Fortune 500 companies over a decade. Our analysts are constantly tracking various high growth markets and identifying hidden opportunities in each sector or the industry. We provide one of the industry’s best quality syndicate as well as custom research reports across 10 different industry verticals. We are committed to deliver high quality research solutions in accordance to your business needs. Our industry standard delivery solutions that ranges from the pre consultation to after-sales services, provide an excellent client experience and ensure right strategic decision making for businesses.

For more information please contact:

Next Move Strategy Consulting

5th Floor 867

Boylston St, STE 500,

Boston, MA 02116, U.S.

E-Mail: [email protected]

Direct: +18577585017

Website: www.nextmsc.com

About the Author

Tania Dey is an experienced Content Writer specializing in digital transformation and market insights. She creates data-driven content that boosts visibility and aligns with emerging trends. Known for simplifying complexity, she delivers engaging narratives that help organizations stay competitive

Tania Dey is an experienced Content Writer specializing in digital transformation and market insights. She creates data-driven content that boosts visibility and aligns with emerging trends. Known for simplifying complexity, she delivers engaging narratives that help organizations stay competitive

About the Reviewer

Sanyukta Deb is a skilled Content Writer and Digital Marketing Team Leader, specializing in online visibility strategies and data-driven campaigns. She excels at creating audience-focused content that boosts brand presence and engagement, while also pursuing creative projects and design interests

Sanyukta Deb is a skilled Content Writer and Digital Marketing Team Leader, specializing in online visibility strategies and data-driven campaigns. She excels at creating audience-focused content that boosts brand presence and engagement, while also pursuing creative projects and design interests

Add Comment