Mexico Distributed Control System Market (DCS) by Component (Hardware, Software, and Services), by Architecture (Centralized Controller Systems, Hybrid / Distributed Hybrid Systems, and Fully Redundant High-Availability Systems), by Application (Batch, and Continuous Process), by Project Type (New Construction, Replacement, and Upgrade/Expansion), by Plant Size (Small, Medium, and Large), and by End User (Oil & Gas, and others) - Opportunity Analysis and Industry Forecast 2024–2030

Industry: Semiconductor & Electronics | Publish Date: 29-Jul-2025 | No of Pages: 174 | No. of Tables: 133 | No. of Figures: 77 | Format: PDF | Report Code : SE940

Market Definition

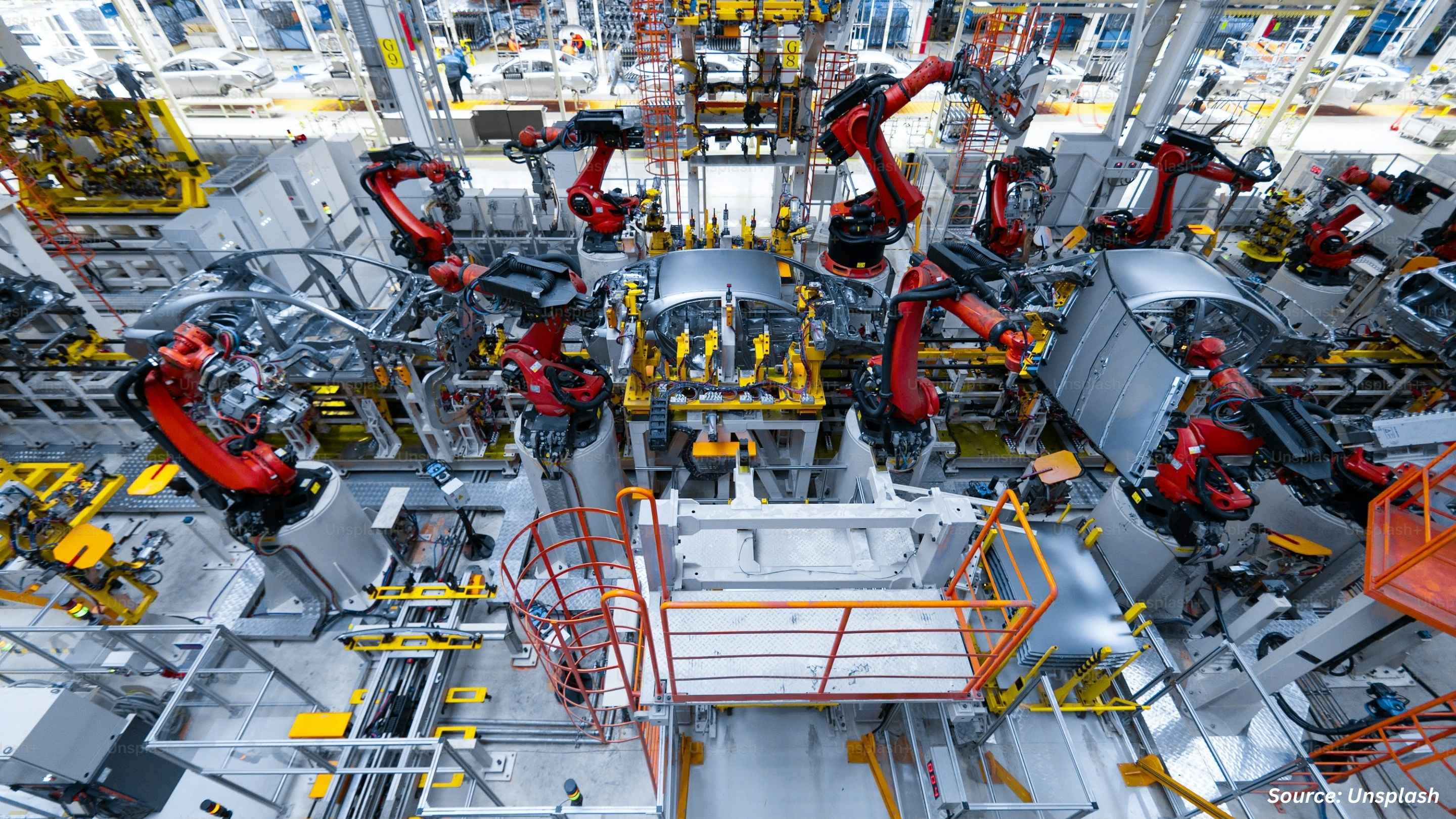

Mexico Distributed Control System (DCS) Market was valued at USD 1.09 billion in 2023, and is predicted to reach USD 1.80 billion by 2030, with a CAGR of 7.2% from 2024 to 2030. A Distributed Control System (DCS) is a computer-based control system widely used to manage and automate industrial processes. It consists of a network of controllers distributed throughout industrial facilities, allowing for communication and coordination in automating various processes. These systems are applied in various industries, including chemicals, petrochemicals, pharmaceuticals, food and beverages, and power generation.

DCS systems are particularly valuable in large-scale industrial processes where automation and control are crucial, such as in oil refineries, chemical plants, and power stations. They oversee operations like drilling, refining, blending, manufacturing, filtration, and disinfection, ensuring precision, efficiency, and safety.

The use of DCS systems offers several advantages, including improved process control, increased efficiency, enhanced safety, and reduced downtime. DCS achieves this by spreading control functions across multiple controllers, providing redundancy and fault tolerance. This means that even if one controller fails, industrial processes can continue without interruptions.

DCS systems have become essential in modern industrial automation, significantly improving the reliability and efficiency of industrial processes. They also enhance safety by enabling real-time control and process monitoring. They can identify potential safety hazards and promptly alert operators for corrective actions. DCS systems also play a vital role in predictive maintenance, allowing proactive maintenance practices to minimize downtime. They collect and analyze data from sensors, providing valuable insights for continuous process improvement.

Key Players Fuelling DCS Market Growth in Mexico through Innovation and Industry Solutions

The DCS market in Mexico experiences growth due to the proactive efforts of major industry players. Their focus on innovation and the provision of tailored solutions to sectors like oil & gas and mining significantly contribute to market expansion. By introducing advanced technologies and addressing industry-specific needs, these key players drive the adoption and effectiveness of Distributed Control Systems, ultimately fostering market growth.

For instance, in January 2023, ABB established a new regional operations center in Merida, Yucatan. An initial USD 1 million investment was made for the Mexico Technology and Engineering Center (MXTEC) to help the technology leader reach higher project delivery capacity and increase competitiveness.

It intends to lead to a rise in engineering capacity of around 25%, with projects necessitating commissioning of distributed control system (DCS) for the ABB Ability System 800xA at client locations. In addition, the International Trade Administration stated that Mexico was the fourth-largest oil producer in the Americas after the U.S, Canada, and Brazil in 2021, producing 1.9 million barrels per day. The oil & gas industry is one of the major users and contributors of DCS technology.

Government-Led Refinery Expansion Initiatives Propel DCS Market Growth in Mexico

The market experiences substantial growth driven by government initiatives, particularly the construction of new refinery plants. These efforts foster the expansion of the Distributed Control System (DCS) market, as they create heightened demand for advanced automation solutions to manage and optimize the complex operations within these facilities. As a result, DCS systems play a pivotal role in enhancing efficiency, safety, and productivity, aligning with the broader objectives of these government-led initiatives and propelling market growth.

For instance, in July 2022, the government of Mexico opened a major oil refinery, Olmeca refinery. The project is owned and operated by state-run oil company Pemex, which is expected to further create an opportunity for the DCS market in the country.

The Risk Associated with Cybercrimes Hampers the Market Growth in Mexico.

DCS systems are inclined to cyberattacks as they are networked and computerized. Cybercriminals can gain unauthorized access to DCS systems, compromise sensitive data, and disrupt critical infrastructure, causing significant financial losses and reputational damage. The consequences of a successful cyber-attack on a DCS system can be severe, especially in industries such as power generation, oil & gas, and chemical processing, where disruptions can have significant environmental and public safety implications.

Modular and Flexible DCS Systems: Unlocking Opportunities for Enhanced Automation

The introduction of modular and flexible DCS systems can create ample growth opportunities for DCS market. Traditionally, DCS systems have been highly centralized and monolithic, with large-scale installations that are expensive and complex to install and maintain.

However, introduction of modular and flexible DCS systems is changing this paradigm. Modular systems are designed to be more flexible and scalable, with a modular architecture that allows easy integration with other systems and components. This makes it easier to customize DCS systems to meet specific needs of individual organizations, without the need for costly and time-consuming customization.

These systems can help to improve production efficiency, reduce costs, and enhance product quality, which is expected to propel demand for DCS systems across a range of industries, including manufacturing, energy, and process industries.

ABB’s modular-enabled process automation solution that combines an orchestration layer is one of the major examples of modular and flexible DCS system. It also consists of a module layer integrated with module type packages (MTPs) technology for cost-effective modularization. This solution is designed to provide end-users such as mining, pharmaceuticals, and biotech with an automation solution that can fit their applications better than Programmable Logic Controllers (PLCs) and costs less than a traditional DCS.

Competitive Landscape

The Mexico distributed control system (DCS) industry includes several market players such as Yokogawa Electric Corporation, Hitachi Ltd., Omron Corporation, Emerson Electric Co., Mitsubishi Electric Corporation, ABB Ltd., Rockwell Automation Inc., Honeywell International Inc., Valmet OYJ, Toshiba Corporation, Schneider Electric SE, General Electrics, Ingeteam Corporation S.A, Azbil Corporation, and Siemens AG.

Mexico Distributed Control System (DCS) Market Key Segments

By Component

-

Hardware

-

Controller

-

I/O

-

Workstation

-

Networking Hardware

-

-

Software

-

Service

-

Integration and Implementation

-

Managed Services

-

Support and Consultation

-

By Architecture

-

Centralized Controller Systems

-

Hybrid / Distributed Hybrid Systems

-

Fully Redundant High-Availability Systems

By Application

-

Batch

-

Continuous Process

By Project Type

-

New Construction

-

Replacement

-

Upgrade/Expansion

By Plant Size (Controller I/O)

-

Small (Greater than 5000 I/O)

-

Medium (5000 to 15000 I/O)

-

Large (Less than 15000 I/O)

By End User

-

Oil & Gas

-

Upstream

-

Midstream

-

Downstream and Refineries

-

-

Chemicals & Refining

-

Energy & Power

-

Thermal Power Plants

-

Renewable and Battery Storage Plants

-

Nuclear Power Plants

-

-

Pulp & Paper

-

Metals & Mining

-

Pharmaceutical & Biotech

-

Food & Beverages

-

Cement & Glass

-

Water & Wastewater

-

Others

Key Players

-

Yokogawa Electric Corporation

-

Hitachi Ltd.

-

Omron Corporation

-

Emerson Electric Co.

-

Mitsubishi Electric Corporation

-

ABB Ltd.

-

Rockwell Automation Inc.

-

Honeywell International Inc.

-

Valmet OYJ

-

Toshiba Corporation

-

Schneider Electric SE

-

General Electrics

-

Ingeteam Corporation S.A

-

Azbil Corporation

-

Siemens AG

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2023 |

USD 1.09 Billion |

|

Revenue Forecast in 2030 |

USD 1.80 Billion |

|

Growth Rate |

CAGR of 7.2% from 2024 to 2030 |

|

Analysis Period |

2023–2030 |

|

Base Year Considered |

2023 |

|

Forecast Period |

2024–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Growth Factors |

The presence of major major industry players. The increasing government initiatives. |

|

Companies Profiled |

15 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

Speak to Our Analyst

Speak to Our Analyst