Bakery Processing Equipment Market Innovations and Trends

Published: 2025-09-17

The bakery processing equipment market is experiencing significant growth, driven by advancements in automation, sustainability, and consumer demand for diverse baked goods. In 2025, the market is predicted to reach USD 20.21 billion by 2030 with a CAGR of 7.0% from 2025-2030.

Rademaker to Showcase Cutting-Edge Bakery Innovations at IBIE 2025

Rademaker, a leading manufacturer of industrial baking equipment, is preparing to showcase its newest innovations at IBIE 2025. Offering advanced solutions for croissants, bread, Danish and puff pastries, pies and quiches, pizza, doughnuts, pita, and other flatbreads, the company continues to drive efficiency and innovation in bakery production.

The company intends to showcase the following:

-

Next-Generation Pizza Topping Line: Rademaker’s latest Pizza Topping Line is engineered for fully automated pizza production. A standout feature is the new Pizza Sauce Depositor, making its North American debut. The line also incorporates the Pizza Strewing System, capable of handling a wide variety of toppings, including cheese, vegetables, IQFs, and meats. Designed for precision, the system includes a recirculation mechanism to reduce waste. By utilizing smart data collection, the strewing process is continuously optimized, with algorithms monitoring and adjusting material flow in real time to maximize efficiency, according to Rademaker.

-

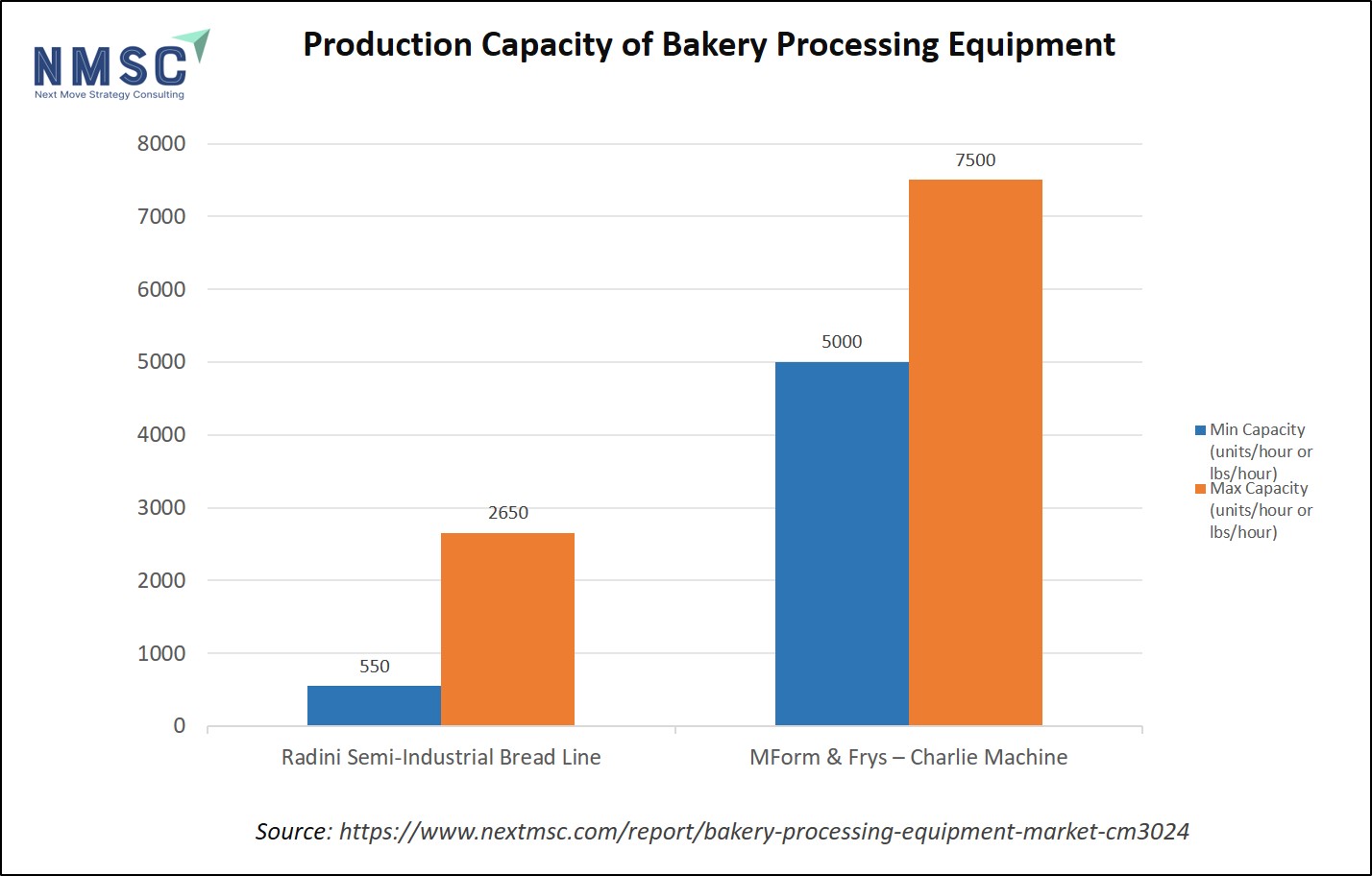

Radini Semi-Industrial Bread Line: Rademaker’s new Radini Bread Line is set to debut in the North American market. The line is designed to handle between 550 and 2,650 pounds of bread dough per hour, accommodating a wide range of dough types. Built on the principle that “rework is a choice,” the system is designed to help bakeries reduce waste while boosting efficiency. Its modular setup supports both automatic and manual shaping, making it ideal for producing hand-shaped breads, the company notes. Mobile units ensure precise cutting, molding, and rounding of dough with consistent weight and size. Following IBIE, the line will be installed at Rademaker’s newly launched Experience Center in Chicago, where customers can test and develop their products.

-

Enhanced Laminating System: Rademaker has upgraded its lamination technology to improve fat layer stability and ensure uniform dough sheet consistency, the company says. These enhancements reflect current product trends, focusing on higher dough quality and consistency. The system’s operation has also been streamlined, making it easier to handle while boosting product reproducibility.

-

New Bread Line Pre-Sheeter: The Dynamic Pre-Sheeter System (DSS), known for converting dough batches into uniform, consistent sheets, has been further advanced, Rademaker reports. With the addition of a reduction station, the DSS now features a smaller footprint, a wider processing range, and the potential to reduce dough rework.

-

Form & Frys: This year, Rademaker completed the acquisition of Form & Frys Maskinteknik, a Danish company recognized for its advanced bakery equipment. According to the company, the move supports Rademaker’s long-term strategic goals and strengthens its ability to deliver specialized solutions to the bakery industry. Among Form & Frys’ offerings, the Charlie stands out as the most flexible machine, capable of folding a wide variety of products at rates of 5,000 to 7,500 units per hour. Additionally, a pizza crust folder will be showcased, enabling pizza producers to expand their product range with unique offerings.

Live Demonstrations by the Dutch Boulangerie Team

The acclaimed Dutch Boulangerie Team will host daily live demonstrations at the Rademaker booth. Using industrially produced dough sheets from Rademaker’s Radini lines, the bakers will highlight the latest product trends. Known for their passion and expertise, the team looks forward to interacting with visitors, sharing insights, and showcasing their skills in both artisanal and industrial baking, the company notes.

|

Equipment/Line |

Min Capacity (units/hour or lbs/hour) |

Max Capacity (units/hour or lbs/hour) |

|

Radini Semi-Industrial Bread Line |

550 lbs/hour |

2,650 lbs/hour |

|

Form & Frys – Charlie Machine |

5,000 products/hour |

7,500 products/hour |

Summary:

Rademaker, a leader in industrial baking equipment, will unveil its latest innovations at IBIE 2025, including automated pizza topping lines, the Radini semi-industrial bread line, enhanced laminating systems, and advanced pre-sheeters. Following its acquisition of Form & Frys, the company will also showcase versatile folding and pizza crust equipment. Daily live demonstrations by the award-winning Dutch Boulangerie Team will highlight product trends and techniques using Rademaker’s Radini dough sheets.

AMF and Puratos Launch Innovative Pilot Bakery to Transform Product Development

AMF Bakery Systems, a global leader in bakery automation, has announced a strategic partnership with Puratos to launch the Puratos Pilot Bakery – Powered by AMF, a cutting-edge facility at Puratos’ U.S. Headquarters in Pennsauken, New Jersey.

Puratos Pilot Bakery: A Collaborative Innovation Hub

Developed over three years of collaboration, the Puratos Pilot Bakery combines Puratos’ expertise in ingredients and formulations with AMF Bakery Systems’ advanced equipment and integrated automation solutions. The facility offers a hands-on environment where commercial bakers can co-create, test, and scale new products efficiently and confidently.

“This partnership brings together two of the most respected names in the baking industry, leveraging our shared vision to enable smarter, faster, and more effective product development and commercialization for our bakery customers,” said Jason Ward, President and CEO of AMF Bakery Systems. “This unique collaboration will deliver significant benefits to the industry. As we pursue our moonshot vision for the Lights Out Bakery, AMF is committed to working with forward-thinking suppliers who share our goal of advancing the baking industry through data-driven automation and sustainable innovation.”

Features of the New Pilot Bakery

-

Flexible, Realistic Production Equipment: The bakery is equipped with versatile machinery designed to replicate real-world production environments.

-

Hygienic Design: All equipment is built to meet strict hygiene standards, ensuring safe and clean operations.

-

Process Refinement: Bakers can optimize recipes and production processes, helping reduce waste and improve efficiency.

-

Minimized Disruption for New Products: Testing and development in the pilot bakery allows new products to be trialed without affecting operations in the customer’s own facilities.

-

Integration with Sensory Lab & Innovation Center: Customers can access the nearby Puratos Sensory Lab and Innovation Center to gather real-time consumer feedback.

-

Accelerated, Targeted Innovation: The combination of practical testing and consumer insights ensures faster, more precise product development.

Industry Leadership on the New Collaboration

Ken Newsome, Executive Chairman of Markel Food Group, which oversees AMF, highlighted the significance of the launch:

“This partnership establishes a new benchmark for the commercial baking industry, demonstrating how real consumer insights can be effectively integrated into product development. It marks a significant advance toward the next era of fast, insight-driven innovation for bakers worldwide.”

Summary:

AMF Bakery Systems and Puratos have partnered to unveil the Puratos Pilot Bakery at Puratos’ U.S. headquarters in New Jersey. The facility combines AMF’s advanced automation with Puratos’ ingredient expertise, providing bakers a hands-on environment to co-create, test, and scale new products. Designed with flexible, hygienic equipment and integrated with the Puratos Sensory Lab, the bakery enables faster, insight-driven innovation while minimizing disruption to customer operations. Industry leaders highlight the collaboration as a new benchmark for consumer-focused, data-driven bakery development.

Next Steps

-

Explore Innovations at IBIE 2025: Visit Rademaker's booth to experience firsthand the latest advancements in bakery processing equipment.

-

Collaborate at the Puratos Pilot Bakery: Utilize the facility to co-create, test, and scale new products efficiently.

-

Stay Informed on Market Trends: Monitor industry reports and exhibitions to keep abreast of emerging technologies and market dynamics.

-

Invest in Automation: Consider integrating advanced automation solutions to enhance efficiency and meet evolving consumer demands.

-

Engage with Industry Leaders: Participate in forums and workshops to gain insights and foster collaborations within the bakery industry.

About the Author

Karabi Sonowal is an experienced SEO Executive and Content Writer in digital marketing. She excels in SEO, content creation, and data-driven strategies that boost online visibility and engagement. Known for simplifying complex concepts, Karabi creates impactful content aligned with industry trends.

Karabi Sonowal is an experienced SEO Executive and Content Writer in digital marketing. She excels in SEO, content creation, and data-driven strategies that boost online visibility and engagement. Known for simplifying complex concepts, Karabi creates impactful content aligned with industry trends.

About the Reviewer

Sanyukta Deb is a skilled Content Writer and Digital Marketing Team Leader, specializing in online visibility strategies and data-driven campaigns. She excels at creating audience-focused content that boosts brand presence and engagement, while also pursuing creative projects and design interests.

Sanyukta Deb is a skilled Content Writer and Digital Marketing Team Leader, specializing in online visibility strategies and data-driven campaigns. She excels at creating audience-focused content that boosts brand presence and engagement, while also pursuing creative projects and design interests.

Add Comment