How AI and Machine Learning are Transforming Predictive Analytics in Intralogistics

Published: 2025-09-11

Introduction: A New Era in Intralogistics with AI and Machine Learning

Intralogistics the management and flow of materials, products, and information within a facility as been revolutionized in recent years by the integration of cutting-edge technologies like Artificial Intelligence (AI) and Machine Learning (ML). These technologies are enhancing predictive analytics, enabling companies to optimize their operations, improve efficiency, and reduce costs. The global intralogistics market, which includes automation systems, software, and analytics tools, is undergoing a transformation as AI and ML algorithms evolve to forecast demand, optimize inventory, and streamline supply chain management.

As companies strive for greater efficiency in warehouse management, distribution centers, and manufacturing facilities, predictive analytics powered by AI and ML is becoming a game-changer. Intralogistics is no longer a simple process of moving goods from one place to another. It is a complex, data-driven system where AI and ML algorithms are used to predict outcomes, anticipate disruptions, and optimize workflows. According to a 2024 report from the U.S. Department of Commerce, AI-driven predictive analytics have the potential to cut logistics costs by 20-25%, further highlighting the importance of these technologies in transforming the sector.

This blog explores how AI and ML are reshaping predictive analytics in intralogistics, focusing on the latest trends, applications, and innovations that are driving growth in the industry.

AI and Machine Learning: A Game-Changer in Predictive Analytics

AI and ML represent a paradigm shift in decision-making for intralogistics. Unlike traditional predictive analytics, which relied on historical data and static statistical models, AI and ML enable real-time processing of vast datasets, delivering highly accurate and adaptive predictions.

Curious about the Intralogistics Market Report? Grab a FREE Sample Now!

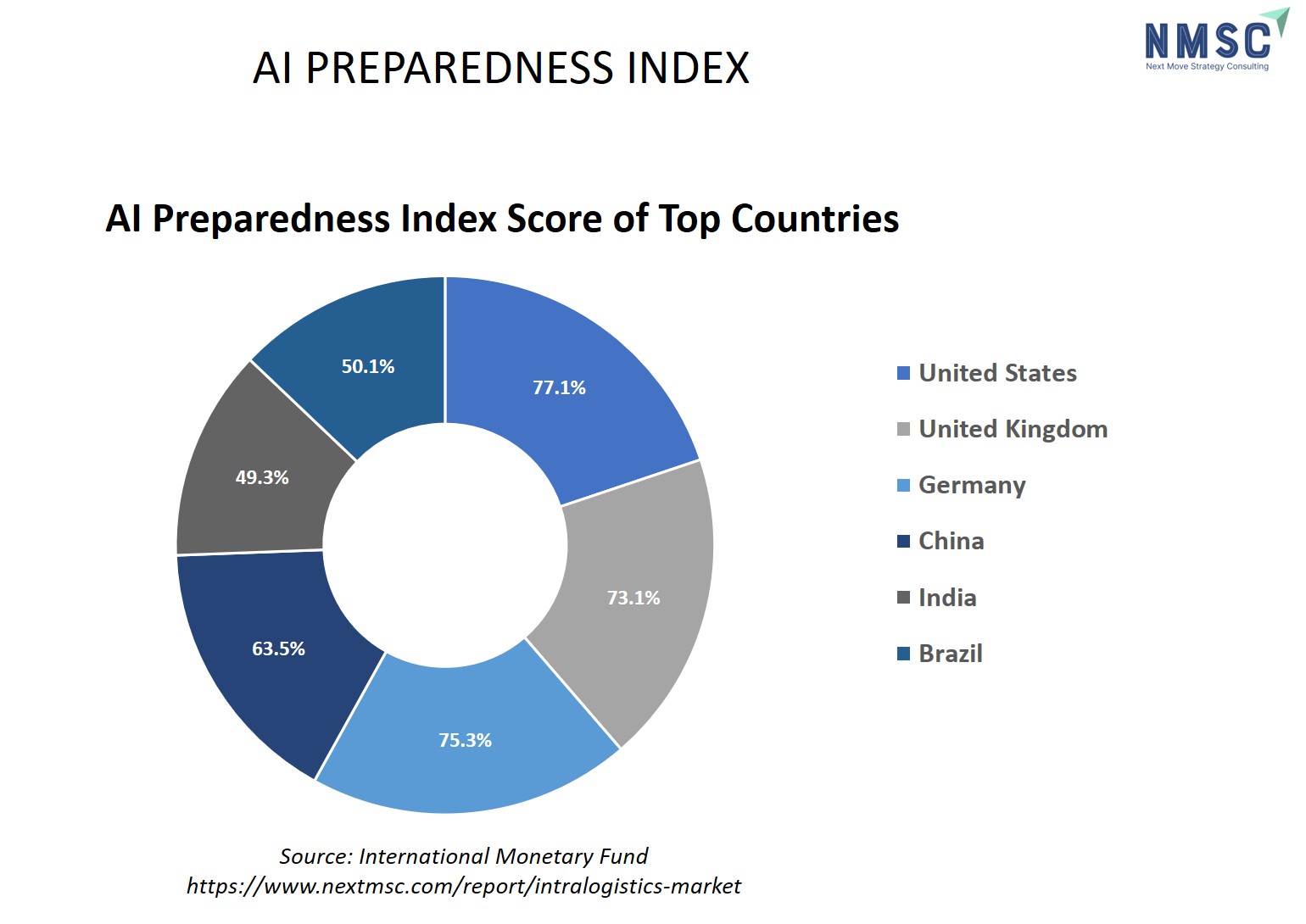

There is a substantial investment in AI by top countries across the globe as depicted in the pie chart below:

Predictive analytics in intralogistics leverages historical and real-time data to forecast events such as demand fluctuations, delivery delays, equipment failures, or inventory shortages. ML algorithms continuously learn from new data, refining predictions over time. For example, in warehouse management, AI-powered predictive analytics can forecast product demand based on customer trends, seasonality, and supply chain disruptions, enabling optimized inventory levels to prevent stockouts or overstocking.

For example, in warehouse management, AI-powered predictive analytics can forecast product demand based on customer trends, seasonality, and supply chain disruptions, enabling optimized inventory levels to prevent stockouts or overstocking. In 2024, Locus Robotics launched an AI-powered predictive analytics module for its warehouse robots, reducing order fulfillment times by 20% through dynamic task allocation based on demand forecasts. Similarly, Zebra Technologies introduced its AI-driven FulfillmentEdge platform in 2024, improving warehouse throughput by 24% by optimizing picking routes and predicting inventory needs.

Applications of AI and ML in Predictive Analytics for Intralogistics

1. Demand Forecasting and Inventory Management

AI and ML algorithms excel at predicting customer demand by analyzing variables like historical sales, consumer behavior, and external factors such as weather, holidays, and economic conditions. These insights enable companies to maintain optimal inventory levels, reducing waste and improving customer satisfaction.

A 2024 European Commission study found that AI-powered demand forecasting can improve inventory accuracy by over 30%, minimizing stockouts and enhancing operational efficiency. Dynamic replenishment systems, powered by ML, ensure warehouses are stocked efficiently without overstocking. For instance, Walmart reported in 2024 that its AI-driven inventory system reduced excess inventory by 15%, saving millions annually.

2. Predictive Maintenance of Intralogistics Equipment

Unplanned equipment downtime cripple intralogistics operations. AI and ML enable predictive maintenance by analyzing real-time data from sensors embedded in machinery like conveyor belts, robotic arms, or automated guided vehicles (AGVs). These models predict potential failures, allowing proactive maintenance scheduling.

A 2024 U.S. Department of Energy report highlighted that AI-powered predictive maintenance can reduce maintenance costs by up to 30% and improve equipment reliability by 25%. In 2025, a post on X from SupplyChainAi noted a 35% efficiency boost in pilot warehouses using AI-driven predictive maintenance for autonomous robots, showcasing real-world impact.

3. Route Optimization and Supply Chain Planning

AI and ML are also transforming how intralogistics companies optimize their delivery routes and supply chain processes. Traditional route optimization relied on static maps and historical data. However, AI-driven systems use real-time data from traffic patterns, weather conditions, and even GPS signals to continuously update routes in real-time.

In 2024, DHL launched an AI-powered route optimization platform that has significantly reduced fuel consumption and delivery times. The platform uses machine learning algorithms to predict traffic conditions, estimate delivery times, and adjust routes accordingly, resulting in an average 15% reduction in fuel costs and 20% faster deliveries.

4. Robotic Process Automation (RPA) and AI

AI-powered robots equipped with sensors and cameras are transforming material handling, sorting, and inventory management in warehouses. Predictive analytics guide these robots to follow the most efficient paths, reducing energy consumption and increasing throughput.

Amazon’s AI-driven robotic warehouses, expanded in 2024, achieved a 40% increase in operational efficiency, according to a McKinsey report. In 2025, Siemens partnered with NVIDIA to integrate digital twin technology with AI-powered robots, enabling real-time simulation and optimization of warehouse workflows.

Cost Structure of Intralogistics Projects: Industry and Equipment Size Considerations

As AI and machine learning drive innovations in predictive analytics within the intralogistics sector, understanding cost structures is essential for businesses adopting these technologies. Costs can vary significantly depending on industry size and equipment scale, with smaller industries facing lower initial costs due to simpler requirements, while larger industries require more advanced systems that demand higher investments. The breakdown of these costs, depicted in the tables below, helps businesses evaluate potential investments in AI and ML technologies to optimize operations and supply chains effectively.

Intralogistics Projects Cost by Industry Size

|

Industry Size |

Low End Cost (in USD) |

High End (in USD) |

|

Small Industry |

5,12,000 |

10,75,000 |

|

Medium Industry |

XXX |

XXX |

|

Large Industry |

XXX |

XXX |

|

Global Average (Consolidated) |

XXX |

XXX |

Intralogistics Projects Cost by Equipment Size

|

Cost Component |

Enterprise Size |

Low-End Cost (in USD) |

High-End Cost (in USD) |

|

Hardware (One-Time) |

Small |

5,00,000 |

10,00,000 |

|

Medium |

XXX |

XXX |

|

|

Large |

XXX |

XXX |

|

|

Software (One-Time/Subscription) |

Small |

XXX |

XXX |

|

Medium |

XXX |

XXX |

|

|

Large |

XXX |

XXX |

|

|

Services (Each-Year) |

Small |

XXX |

XXX |

|

Medium |

XXX |

XXX |

|

|

Large |

XXX |

XXXX |

Note: For the latest and in-depth insights, you can reach out to us.

Latest Industry Developments and Company Innovations

Several companies have recently launched innovative solutions that harness the power of AI and ML in intralogistics, further accelerating the industry’s adoption of predictive analytics.

1. Siemens and the Launch of the "Xcelerator" Platform

In 2024, Siemens launched its AI-driven "Xcelerator" platform, designed to optimize supply chain management in real-time. The platform integrates predictive analytics to enhance warehouse and distribution center operations, offering insights into potential bottlenecks and inefficiencies. Siemens’ solution leverages machine learning algorithms to predict demand fluctuations and optimize inventory management, all while improving operational performance and reducing costs.

2. FedEx’s AI-Powered Supply Chain Optimization

FedEx, a global leader in logistics, has been leveraging AI and ML to optimize its global supply chain. In 2024, the company introduced an AI-powered platform that analyzes vast amounts of logistics data to predict shipment delays, identify supply chain risks, and suggest corrective actions. This platform helps FedEx reduce operational disruptions and improve delivery timelines, contributing to enhanced customer satisfaction and lower operational costs.

3. IBM’s AI for Intralogistics

IBM has also entered the intralogistics space with its AI-powered solutions, which focus on improving predictive analytics for warehouses and supply chains. In 2024, the company introduced its Watson AI-powered intralogistics platform, which uses machine learning to predict equipment failure, optimize warehouse space, and streamline operations. By integrating with IoT sensors, the platform offers real-time analytics that help businesses make better decisions and reduce downtime.

Challenges and the Future of AI in Intralogistics

While AI and ML are driving transformative changes in intralogistics, there are still several challenges to overcome. The implementation of AI-driven predictive analytics requires significant investment in technology, infrastructure, and training. Smaller companies, in particular, may struggle with the upfront costs of AI adoption.

Moreover, integrating AI systems with existing intralogistics infrastructure can be complex. Legacy systems may not be compatible with new AI-driven technologies, leading to potential disruptions during the transition.

Despite these challenges, the future of AI in intralogistics looks promising. As technology continues to evolve, AI and ML will play an even greater role in optimizing predictive analytics, improving operational efficiency, and reducing costs. Companies that invest in these technologies will be well-positioned to lead the way in the next generation of intralogistics operations.

Conclusion: The Future of Intralogistics is Predictive and AI-Driven

AI and Machine Learning are revolutionizing predictive analytics in the intralogistics industry by enabling more accurate forecasting, smarter inventory management, optimized delivery routes, and predictive maintenance. As the technology continues to evolve, it will unlock even more potential for businesses to improve their operations and stay competitive in an increasingly complex and fast-paced market.

With key industry players like Siemens, FedEx, and IBM driving innovations, the intralogistics sector is moving toward a future where AI and ML are at the core of every decision. As predictive analytics become more sophisticated, businesses will be able to anticipate disruptions, optimize workflows, and drive efficiencies in ways that were once unimaginable. While challenges remain, the continued development and adoption of AI and ML technologies will undoubtedly shape the future of intralogistics, making it more efficient, cost-effective, and adaptable to the ever-changing demands of the global marketplace.

About the Author

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media.

Sukanya Dey is a passionate and insightful writer with over three years of experience, she excels in providing clients with in-depth research and valuable insights, helping them navigate complex business challenges. She has a keen interest in various industries, including Retail and Consumer, Healthcare, Manufacturing, Automotive, and ICT & Media.

About the Reviewer

Debashree Dey is a skilled Content Writer, PR Specialist, and Assistant Manager with strong expertise in Digital Marketing. She specializes in crafting visibility strategies and delivering impactful, data-driven campaigns. Passionate about creating engaging, audience-focused content, she helps brands strengthen their online presence. Beyond work, she draws inspiration from creative projects and design pursuits.

Debashree Dey is a skilled Content Writer, PR Specialist, and Assistant Manager with strong expertise in Digital Marketing. She specializes in crafting visibility strategies and delivering impactful, data-driven campaigns. Passionate about creating engaging, audience-focused content, she helps brands strengthen their online presence. Beyond work, she draws inspiration from creative projects and design pursuits.

Add Comment