Intralogistics Market by Component (Hardware (AS/RS (Unit-Load, Mini-Load, VLMs, Carousel), Industrial Robots, Mobile Robots (AGV, and AMR), Conveyor Systems, Sortation Systems, Software (WMS, TMS, Yard Management, and Others) and Services), and by End User (Retail and E-commerce, Automotive, Food and Beverage, Pharmaceuticals, Aviation, Logistics, Semiconductor & Electronics, Consumer Goods, Others) – Global Opportunity Analysis and Industry Forecast, 2025–2030

Industry: Construction & Manufacturing | Publish Date: 15-May-2025 | No of Pages: 339 | No. of Tables: 242 | No. of Figures: 167 | Format: PDF | Report Code : CM580

US Tariff Impact on Intralogistics Market

Trump Tariffs Are Reshaping Global Business

Industry Overview

The global Intralogistics Market size was valued at USD 63.71 billion in 2024 and is projected to grow to USD 71.61 billion by 2025. Additionally, the industry is expected to continue its growth trajectory, reaching USD 112.17 billion by 2030, with a CAGR of 9.4% from 2025 to 2030. In terms of volume the market size was 1.7 million units in 2024 and is projected to reach 3.5 million units in 2030, with a CAGR of 11.9% from 2025 to 2030.

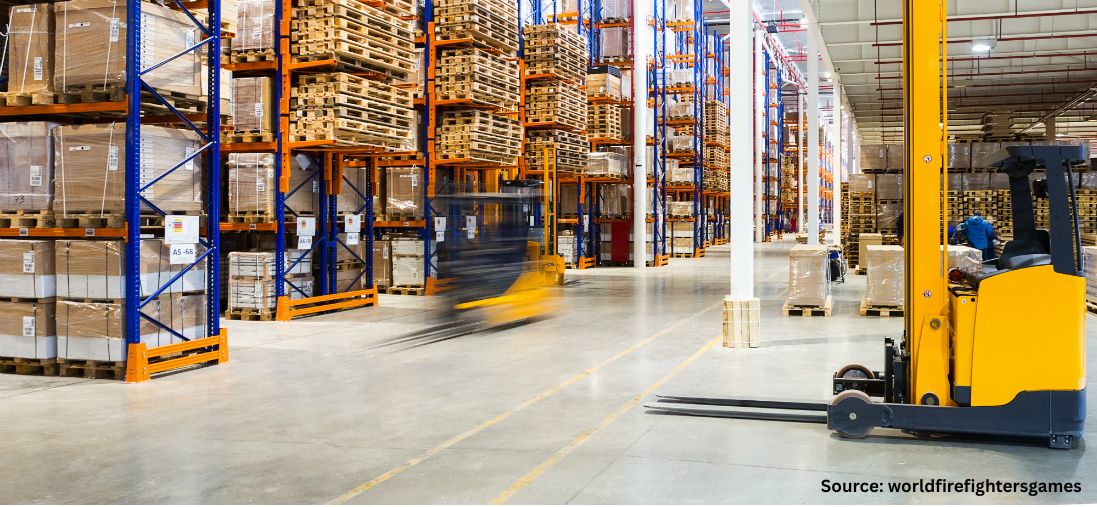

The rapid growth of e-commerce and the automotive industry is driving the market, increasing demand for efficient warehousing and order fulfillment. Additionally, the rise of industrial robots enhances operational efficiency, while AI integration presents opportunities for improved scalability and flexibility. However, high initial costs for automation technologies limit adoption, especially among small businesses. Despite this, AI-driven innovations are expected to drive continued industry growth.

Surge in Online Shopping Propels Growth of the Industry

The rapid expansion of the e-commerce sector is significantly driving the intralogistics market growth. According to a recent report by the International Trade Administration, global B2B e-commerce sales are projected to grow from USD 28.08 trillion in 2024 to USD 36.16 trillion by 2026, underscoring the accelerating digital commerce landscape. This substantial growth in online retail coupled with the rise of omnichannel retailing is placing greater emphasis on the need for efficient warehousing, inventory management, and streamlined order fulfillment processes.

As a result, demand for smart automation systems, robotics, and warehouse management technologies within the intralogistics space is expected to rise sharply, fueling the market’s overall expansion.

Expansion of Automotive Sector Drives the Intralogistics Market Demand

The ongoing expansion of the automotive industry is a significant driver of intralogistics sector growth. As vehicle production scales up, there is a growing need to streamline manufacturing workflows, manage complex supply chains, and ensure the timely delivery of components to assembly lines.

According to the latest forecast by S&P Global Mobility, global new vehicle sales are projected to reach 89.6 million units in 2025, reflecting a 1.7% year-over-year increase and indicating a cautious but steady recovery in the automotive sector. This rising demand for vehicles compels automakers to enhance production capacity and operational efficiency thereby increasing reliance on advanced intralogistics solutions.

Rise in Adoption of Industrial Robots Accelerates the Intralogistics Market Trends

The increasing use of industrial robots is playing a pivotal role in boosting the growth of the market by significantly enhancing operational efficiency, accuracy, and speed in material handling processes. This shift addresses the growing demand for faster, more reliable, and scalable intralogistics operations.

As per the World Robotics 2024 report published by the International Federation of Robotics (IFR), global robot density in factories reached an all-time high of 162 units per 10,000 employees in 2023 that is more than double the 74 units recorded just seven years earlier. Consequently, the demand for advanced intralogistics systems that seamlessly integrate with robotic technologies continues to rise, propelling market expansion.

High Initial Investment Restrains the Intralogistics Market Expansion

A major challenge in the intralogistics sector is the high upfront investment required for automation technologies like conveyors, warehouse management software, mobile robots, and cranes. These systems have significant initial costs, which can be prohibitive for small and medium-sized enterprises.

In addition to acquisition, ongoing expenses for maintenance, software updates, and workforce training further increase the total cost of ownership. This financial burden limits adoption, particularly among businesses with tight budgets, slowing the sector's growth and its potential to optimize supply chains.

Integration of Artificial Intelligence Offers Promising Opportunities for Market Expansion

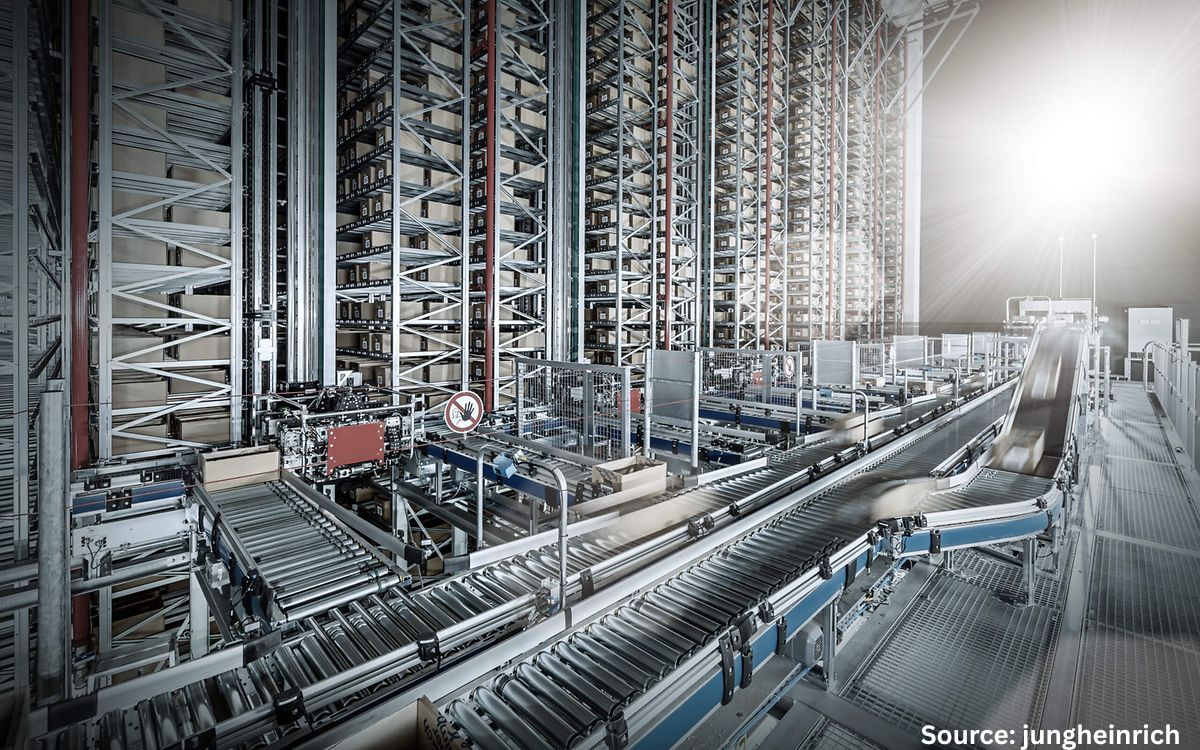

The integration of artificial intelligence (AI) into intralogistics is creating major opportunities for market growth by transforming warehouse operations and improving efficiency. AI-powered robots can navigate complex warehouse environments autonomously, performing tasks such as picking, packing, and sorting while reducing the physical burden on human workers.

A notable example is Nimble Robotics, which in October 2024 secured USD 106 million in Series C funding led by FedEx and reached a USD 1 billion valuation. The company introduced fully autonomous warehouses equipped with general-purpose AI robots capable of adapting to real-time changes in operations. As AI continues to enhance scalability, flexibility, and cost-effectiveness in warehouse automation, it is poised to be a major driver of the market expansion in the near future.

By Component, Hardware Holds the Dominant Share in the Intralogistics Market Report

Hardware continues to lead the market as the core enabler of operational efficiency, reliability, and high performance across demanding industrial environments. Essential intralogistics solutions support seamless material flow, accurate inventory tracking, and rapid order processing.

The rising demand for automation is further accelerating hardware adoption. For instance, Falcon Autotech’s NEO, launched in January 2024, integrates robotics, AI, and sensors to optimize warehouse performance. Government data reinforces this trend—the U.S. International Trade Administration projects global B2B e-commerce to reach USD 36.16 trillion by 2026, while the European Commission highlights the importance of hardware-led automation in meeting industrial productivity goals. Whether in fast-paced fulfillment centers or precision-driven manufacturing lines, high-performance intralogistics hardware is pivotal to sustaining growth and innovation in the intralogistics sector.

By End User, Semiconductor, Holds the Highest CAGR of 12.6%

The semiconductor segment is rapidly emerging as the fastest-growing end-user in the intralogistics sector, driven by its need for precision, contamination control, and automation. Semiconductor manufacturing requires cleanroom-compatible technologies such as AGVs, robotic arms, and automated storage and retrieval systems (AS/RS) to enable just-in-time production and maintain high throughput with minimal error. Recent innovations reflect this demand such as Daifuku Co., Ltd. introduced cleanroom AGVs in March 2024 designed specifically for semiconductor environments.

Regional reports from the U.S. Department of Commerce and the European Commission further underscore increasing investments in advanced automation and Industry 4.0 technologies in chip manufacturing. As a result, the semiconductor sector not only drives demand for cutting-edge intralogistics solutions but also plays a central role in shaping innovation across the broader logistics ecosystem.

North America Region Dominates the Intralogistics Market

North America dominates the intralogistics market share, driven by the strong presence of major industry players and the early adoption of advanced automation technologies. Companies such as Honeywell International Inc., Dematic, and Daifuku Co., Ltd. are making significant investments in AI-powered systems, AMRs, and AS/RS technologies to improve warehouse productivity and reduce operational costs.

Notable developments include Honeywell’s January 2024 acquisition of Transnorm to strengthen its automation capabilities, and Dematic’s March 2024 acquisition of Digital Applications International to integrate advanced robotics into high-throughput distribution centers. These strategic initiatives underscore the region’s leadership in driving technological innovation within the sector.

Additionally, the expanding chemical industry is playing a crucial role in accelerating demand for robust intralogistics solutions across North America. With U.S. chemical exports reaching USD 289 billion in 2024 a 15% increase from the previous year the sector is increasingly dependent on automation for handling hazardous materials and ensuring safety compliance. Falcon Autotech’s AI-powered AS/RS system “NEO,” introduced in January 2024, exemplifies how tailored technologies are meeting the unique needs of chemical and pharmaceutical warehousing. Together, industry-led innovation and sector-specific demand position North America as a key driver of growth and advancement in the global market.

Asia-Pacific is Expected to Show a Steady Growth in the Intralogistics Sector

The Asia-Pacific region is set for steady growth in the market, driven by the booming automotive industry and rapid e-commerce expansion. The automotive sector, particularly in China, is a key growth driver, with domestic vehicle production projected to reach 35 million units by 2025, according to the International Trade Administration. This surge is fueling demand for advanced intralogistics solutions to enhance production efficiency, streamline supply chains, and support complex automotive manufacturing logistics.

In addition, the growing demand for online shopping significantly contributes to the expansion of the market. As consumer expectations for faster deliveries increase, businesses adopt intralogistics technologies to meet these demands by optimizing their operations. According to the Ministry of Commerce and Industry, India’s e-commerce market is projected to reach USD 325 billion by 2030. The rise of online shopping thus plays a crucial role in enhancing the demand for technologies that enable faster, more efficient material handling, inventory management, and delivery processes.

Strategic Analysis of Companies in the Intralogistics Industry

The global intralogistics industry is growing rapidly as key players adopt automation, robotics, and digital technologies to enhance efficiency, speed, and precision in material handling. These technologies are vital for streamlining workflows, reducing costs, and boosting productivity.

A major trend is the deployment of advanced robotic systems for warehouse automation and inventory accuracy. In November 2024, Oriental Motor introduced its OVR Series robots and MRCU Series Integrated Robot Controller to improve system flexibility. Similarly, in September 2024, Kawasaki Robotics and NEURA Robotics launched the CL Series of collaborative robots for safer human-robot interaction.

Additionally, Rapyuta Robotics Inc. launched an Automated Storage and Retrieval System (ASRS) in July 2024, boosting picking productivity and storage efficiency. Strategic collaborations, such as Comau S.p.A.’s partnership with One Equity Partners in July 2024, are further driving further innovation. Despite challenges like high costs and integration complexity, opportunities for AI, and IoT, drives the market growth.

Analysis of Cost Breakdown of Intralogistics Projects by Industry Type and Equipment Size

This analysis presents a comprehensive breakdown of intralogistics project costs, focusing on how expenses vary based on industry size and the scale of equipment deployed. The costs associated with hardware, software, and services are significantly influenced by whether an enterprise falls under a small, medium, or large-scale operation. So here is a detailed analysis on the investment patterns observed across different business categories in intralogistics:

Intralogistics Projects Cost by Industry Size

|

Industry Size |

Low End Cost (in USD) |

High End (in USD) |

|

Small Industry |

5,12,000 |

10,75,000 |

|

Medium Industry |

XXX |

XXX |

|

Large Industry |

XXX |

XXX |

|

Global Average (Consolidated) |

XXX |

XXX |

Intralogistics Projects Cost by Equipment Size

|

Cost Component |

Enterprise Size |

Low-End Cost (in USD) |

High-End Cost (in USD) |

|

Hardware (One-Time) |

Small |

5,00,000 |

10,00,000 |

|

Medium |

XXX |

XXX |

|

|

Large |

XXX |

XXX |

|

|

Software (One-Time/Subscription) |

Small |

XXX |

XXX |

|

Medium |

XXX |

XXX |

|

|

Large |

XXX |

XXX |

|

|

Services (Each-Year) |

Small |

XXX |

XXX |

|

Medium |

XXX |

XXX |

|

|

Large |

XXX |

XXXX |

Note: For more detailed and in-depth analysis you can buy our latest report -

Intralogistics Market Key Segments

By Component

-

Hardware

-

Automated Storage and Retrieval Systems (AS/RS)

-

Unit-Load AS/RS

-

Mini-Load AS/RS

-

Vertical Lift Modules (VLMs)

-

Carousel AS/RS

-

-

Industrial Robots

-

Mobile Robots

-

Automated Guided Vehicle (AGV)

-

Autonomous Mobile Robot (AMR)

-

-

Conveyor Systems

-

Sortation Systems

-

-

Software

-

Warehouse Management System (WMS)

-

Transportation Management System (TMS)

-

Yard Management Software

-

Inventory Management Software

-

Labor Management Software

-

Other Software

-

-

Service

By End-User

-

Retail and E-commerce

-

Automotive

-

Food and Beverage

-

Pharmaceuticals

-

Aviation

-

Logistics

-

Semiconductor & Electronics

-

Consumer Goods

-

Other End Users

By Region

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

The UK

-

Germany

-

France

-

Italy

-

Spain

-

Denmark

-

Netherlands

-

Finland

-

Sweden

-

Norway

-

Russia

-

Rest of Europe

-

-

Asia-Pacific

-

China

-

Japan

-

India

-

South Korea

-

Australia

-

Indonesia

-

Singapore

-

Taiwan

-

Thailand

-

Rest of Asia-Pacific

-

-

RoW

-

Latin America

-

Middle East

-

Africa

-

Key Players

-

Jungheinrich

-

KION Group

-

Midea Group

-

Daifuku Co., Ltd.

-

Honeywell International Inc.

-

SSI Schafer

-

Beumer Group GmbH

-

Knapp AG

-

Symbotic Inc.

-

TGW Logistics Group

-

AutoStore System

-

Toyota Industries Corporation (Vanderlande Industries B.V.)

-

Krones Group

-

Falcon Autotech

-

KEBA Group AG

-

Other Notable Key Players

-

Siemens AG

-

MDP Group

-

Godrej Enterprises

-

Beumer Group

-

Zebra Technologies Corporation

REPORT SCOPE AND SEGMENTATION:

|

Parameters |

Details |

|

Market Size in 2024 |

USD 63.71 Billion |

|

Market Volume in 2024 |

1.7 Million Units |

|

Revenue Forecast in 2030 |

USD 112.17 Billion |

|

Volume Forecast in 2030 |

3.5 Million Units |

|

Value Growth Rate |

CAGR of 9.4% from 2025 to 2030 |

|

Volume Growth Rate |

CAGR of 11.9% from 2025 to 2030 |

|

Analysis Period |

2024–2030 |

|

Base Year Considered |

2024 |

|

Forecast Period |

2025–2030 |

|

Market Size Estimation |

Billion (USD) |

|

Market Volume Estimation |

Million Units |

|

Growth Factors |

|

|

Countries Covered |

28 |

|

Companies Profiled |

20 |

|

Market Share |

Available for 10 companies |

|

Customization Scope |

Free customization (equivalent up to 80 working hours of analysts) after purchase. Addition or alteration to country, regional, and segment scope. |

|

Pricing and Purchase Options |

Avail customized purchase options to meet your exact research needs. |

Speak to Our Analyst

Speak to Our Analyst