Exploring Breakthrough Technologies in Intralogistics Automation

Introduction

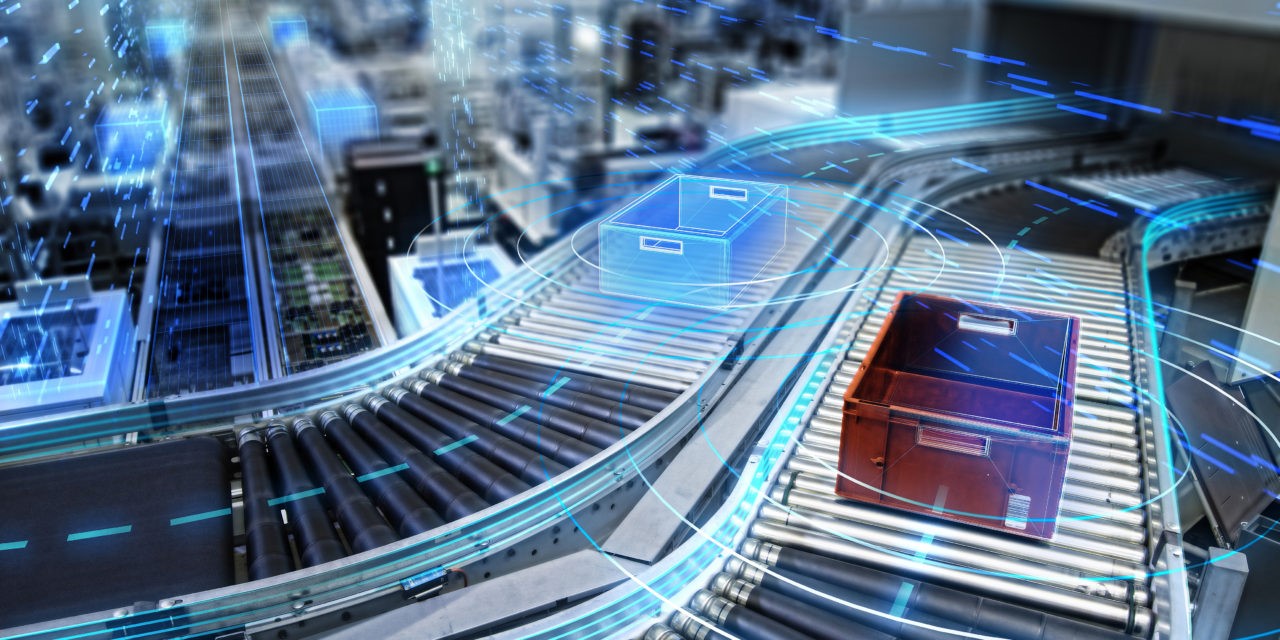

Intralogistics is the process of managing and optimizing internal logistics of a warehouse or distribution center. It involves the movement, storage, and retrieval of goods within a facility, and plays a crucial role in efficiency and profitability of any supply chain operation. With increase in demand for faster and more accurate order fulfillment, importance of intralogistics optimization has also increased.

Here are 5 best practices for optimizing intralogistics operations:

1. Streamline Material Handling Processes: Material handling is a critical aspect of intralogistics, and optimizing it can greatly improve efficiency and reduce costs. One effective way to streamline material handling is by implementing a lean manufacturing approach. This involves eliminating waste, minimizing inventory, and using standardized processes to improve flow and reduce lead times.

2. Invest in Automated Systems: Automated systems such as conveyors, AS/RS, and AGVs can greatly improve intralogistics efficiency by reducing the need for manual labor and eliminating the risk of human error. Automated systems can also improve accuracy, speed, and safety while reducing operating costs.

3. Optimize Warehouse Layout: The layout of a warehouse or distribution center can greatly impact intralogistics efficiency. An optimized layout should minimize travel distances and facilitate efficient material flow. This can be achieved by grouping similar products together, creating efficient picking paths, and using vertical space to maximize storage capacity.

4. Implement Warehouse Management Systems (WMS): A WMS is a software application designed to optimize warehouse operations. It provides real-time visibility into inventory levels, automates order fulfillment processes, and improves accuracy and efficiency. Implementing a WMS can greatly improve intralogistics efficiency and reduce costs.

5. Train and Empower Employees: Success of any intralogistics optimization effort depends on employees responsible for its implementation. Providing comprehensive training and empowering employees to take ownership of their processes can greatly improve intralogistics efficiency. Encouraging employee feedback and participation in continuous improvement efforts create a culture of intralogistics optimization.

New Technologies to Support Automation and Optimization of Intralogistics in the Future:

As the demand for faster, more efficient intralogistics operations continues to grow, new technologies are emerging to help automate and optimize these processes. Here are some crucial technologies that are being developed to support automation and optimization of intralogistics in the future.

1. Transportation technology: New technologies such as track inspection drones and AGVs with laser-controlled navigation for autonomous routing, logistics trains replacing forklifts, or self-organizing conveyor systems will provide more flexibility in intralogistics. Unmanned aerial vehicles (UAVs), sometimes called as drones, are being used to supplement manual track inspections carried out by people on trolleys or trucks with rail wheels.

These drones have cameras and sensors that allow them to capture images, record videos, collect LiDAR data, and transfer that data in real time to remote operators. This enables them to navigate autonomously, avoiding obstacles and adjusting their path in real-time. With this technology, AGVs can be programmed to take the most efficient route between different areas of a warehouse, reducing the time and energy required for material handling tasks.

2. Digital Twin Technology: A digital twin can be used to create a virtual replica of a warehouse, which can be used to optimize the layout of a warehouse, simulate different storage and picking strategies, and test the impact of changes in the supply chain. This technology can be useful to identify bottlenecks and inefficiencies in the supply chain and enable companies to optimize material flow to improve efficiency. Digital twins can improve intralogistics procedures and strengthen supply chains in the future by balancing costs, enhancing availability, and reducing lead times.

Businesses in the logistics and industrial sectors can employ digital twins to manage warehouses, inventory, and products in a more comprehensive, end-to-end manner. For instances, in August 2021, a research project "ARIBIC" was launched by the KION Group in collaboration with LeddarTech, the STARS Lab at the University of Toronto and the Karlsruhe Institute of Technology (KIT). This was a step to enhance already existing digital twin solutions as well as simulation and emulation platforms of KION Group.

3. Humanoid Robots: Humanoid robots are designed to resemble and function like humans, typically equipped with sensors, motors, and other components that enable them to perform a wide range of tasks, including walking, running, and manipulating objects. Humanoid robots can be programmed to perform repetitive and physically demanding tasks that are typically performed by human workers.

This can help to increase efficiency and reduce the risk of workplace injuries. Humanoid robots can work round the clock, without the need for breaks or rest periods, which can help to increase production output and reduce downtime. For instance, Astro, a humanoid robot on wheels from Apptronik, was designed to work alongside human counterparts. Astro presently works in a range of industries, including manufacturing and logistics, and uses machine learning to learn how to pick objects.

Conclusion

The future of intralogistics is one where technology collaborates with human imagination to create a harmonious and highly efficient ecosystem. The breakthroughs discussed in this article mark the inception of a new era, where logistics is not just a series of movements but a symphony of arranged precision. Embracing these technologies is not merely an option; it's a pathway to unlocking unprecedented potential and ensuring that the logistics of tomorrow are smarter, faster, and more responsive than ever before.

About the Author

Sunanda Ghosh is a researcher with more than 3 years of experience. She has a passion for understanding consumer behavior and market trends, and uses her skills in innovative ways to gather and analyze data. Throughout her career, she has worked with a diverse range of global clients across various industries including technology, semiconductor, and energy. She is dedicated to providing valuable insights that can help shape a company's direction and drive success.

Sunanda Ghosh is a researcher with more than 3 years of experience. She has a passion for understanding consumer behavior and market trends, and uses her skills in innovative ways to gather and analyze data. Throughout her career, she has worked with a diverse range of global clients across various industries including technology, semiconductor, and energy. She is dedicated to providing valuable insights that can help shape a company's direction and drive success.

The author can be reached at sunanda.ghosh@nextmsc.com

Leave a Reply