Dry Ramming Mass: Challenges and Industry Outlook

Published: 2025-11-12

Dry Ramming Mass (DRM) is a vital refractory material used for lining coreless induction furnaces, steel-melting units and other high-temperature industrial processes. Its advantages, such as ease of application, minimal moisture content, and high compaction density, make it popular. However, the industry faces several persistent challenges linked to materials, installation and operational conditions.

What is Dry Ramming Mass and Why is it Important?

Dry ramming mass is a “dry” refractory material (i.e., minimal or no added water binder) used by ramming into furnace gaps, achieving high packing density, and then sintering in-situ.

It is key in induction furnaces and foundries because it can help resist metal corrosion, thermal wear, and allows fast furnace turnaround.

Because of this importance, understanding the challenges in its use is critical for furnace reliability, cost-control and safety.

Key Challenges in Using Dry Ramming Mass

1. Inconsistent Raw Material Quality

Because the performance (thermal shock resistance, corrosion resistance, strength) of DRM depends on the quality of the aggregates (silica, magnesia, alumina) and sintering aids, any impurity, variation in grain size, or inconsistency in composition can degrade performance. For example, in one patent it was shown that blending silica with small amounts of magnesia/alumina improved strength at high-temperature use.

Variations in raw material cost and availability also drive cost fluctuations.

2. Improper Mixing, Ramming and Installation

Even with good raw materials, if the dry mass is not compacted properly or if there are voids/air gaps, this may lead to weak spots, cracks or early failure of the lining. The lack of a water binder means that installation technique, vibration/ramming force and layer density are very important. The drying or sintering stage must also be managed carefully. (While direct industry article references are fewer, the patent notes the importance of compaction and filling steps.)

3. Thermal Shock, Sintering Problems and Moisture Sensitivity

DRM must withstand rapid temperature changes during furnace start-up and shutdown. Inadequate sintering (especially near the furnace wall cooling zones) can lead to zones of low strength. The Japanese patent discusses this: “the dry ramming material is sintered and has sufficient strength inside the high-temperature furnace but does not rise to the sintering temperature on the furnace wall side hence strength is reduced.”

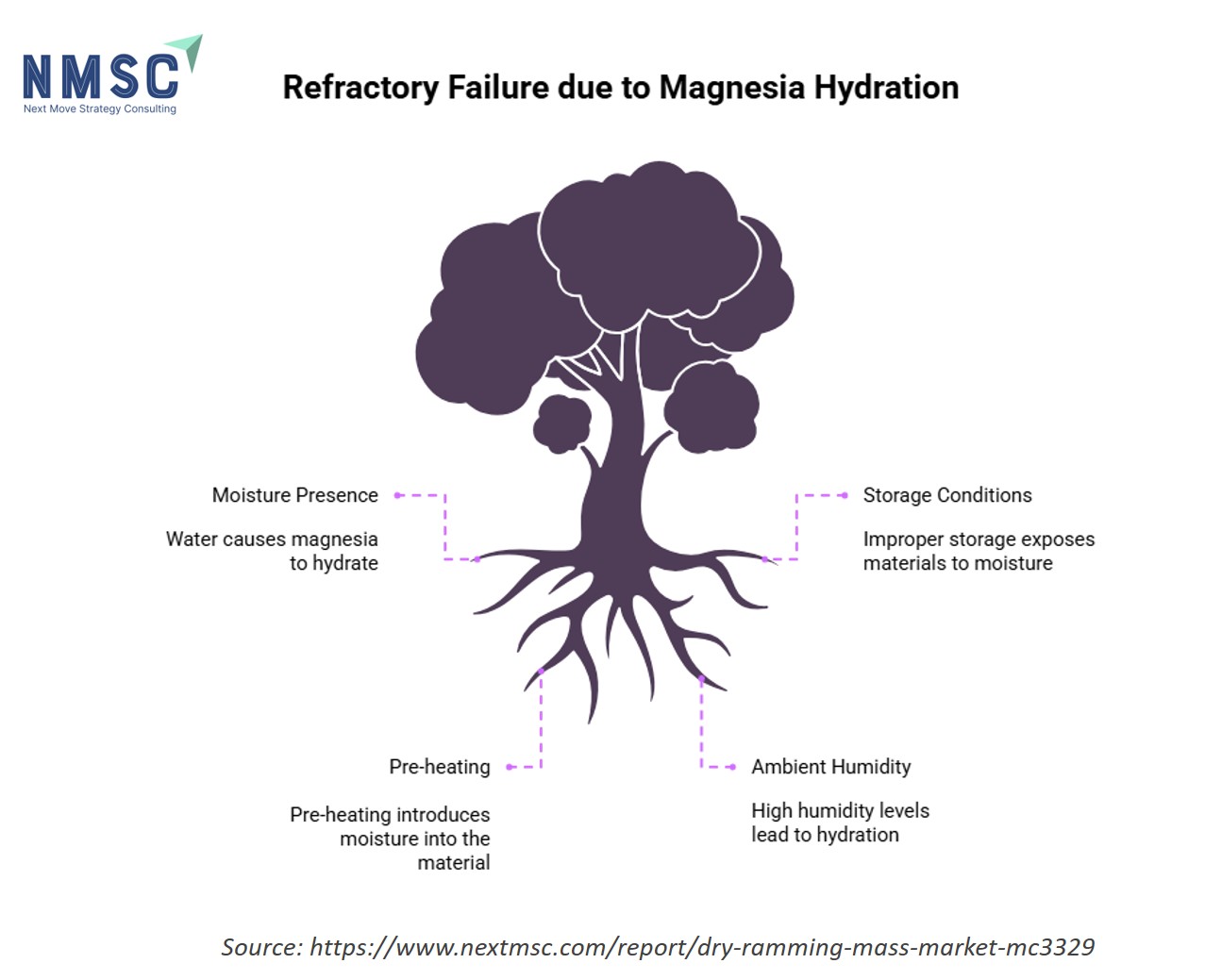

Also, if moisture or water is present (either from storage, pre-heating, or ambient humidity), certain refractory materials like magnesia can hydrate, leading to large volume expansions and failure. For example, hydration of magnesia in refractories was blamed for a smelter lining failure.

4. High Upfront Cost & Competitive Material Pressures

Market reports highlight that one of the key restraints for DRM adoption is the higher upfront cost compared to traditional refractory materials like castables or bricks.

Additionally, competition from alternative refractory technologies and the need to innovate for eco-friendly solutions add to cost and complexity.

5. Skilled Labour and Proper Handling/Storage

Because this is a dry material that requires precise installation technique, vibration/ramming, densification, sintering schedule, and also good storage (to avoid moisture uptake), the skill and process discipline are non-trivial. Any lapse can lead to defects. NextMSC studies list “complexity of manufacturing processes and the need for skilled labour” as a hurdle for the Dry Ramming Mass (DRM) Market.

6. Environmental, Handling and Storage Challenges

While less frequently cited specifically for DRM, general refractory industry work shows that improper handling or exposure to humidity, water leaks, or inadequate pre-heating lead to performance loss (especially for magnesia and other sensitive materials). For example, hydration of magnesia refractories due to unintended water exposure caused major losses.

Storage conditions (for dry ramming mass) matter because moisture uptake before installation can impair sintering and densification.

Next Move Strategy Consulting View

From the vantage of Next Move Strategy Consulting, while the global DRM market is poised for growth (driven by steel, foundry, power generation and infrastructure sectors), addressing these challenges is essential for unlocking full potential.

Key actionable areas include:

-

Ensuring material traceability and quality assurance across aggregates, binders and sintering aids.

-

Strengthening installation protocols, vibration/ramming, layer thickness, pre-heating schedule, sintering.

-

Investing in training and process discipline to handle dry installation methods.

-

Mitigating moisture/handling risk through proper storage, pre-heating and humidity control.

-

Optimising cost vs lifecycle benefits, although upfront cost is higher, better performance (less downtime, longer life) can offset it.

-

Monitoring market dynamics, raw material price volatility, alternative refractory types, regulatory/eco‐pressures.

Companies that can combine advanced DRM formulations with robust installation support, skilled workforce, and good logistics will be better positioned to lead in this sector.

Conclusion

Dry ramming mass continues to play a crucial role in modern metallurgical and foundry operations, serving as a backbone for furnace efficiency and performance. Yet, its true potential is often limited by raw material inconsistencies, improper installation, and inadequate process control. As the refractory industry evolves, overcoming these challenges requires a blend of technology, quality assurance, and skilled application practices.

With manufacturers investing in automated mixing, ready-to-use pre-blends, and training programs for furnace operators, the industry is steadily moving toward more consistent and sustainable operations. Combined with digital monitoring and improved sintering control, these advancements are expected to extend lining life and lower maintenance costs.

In essence, the future of dry ramming mass lies in precision and innovation, where every step from material selection to installation is optimized for reliability, safety, and sustainability.

About the Author

Joydeep Dey is a seasoned SEO Executive, Content Writer, and AI expert with over 2½ years of experience in digital marketing and artificial intelligence. He specializes in SEO strategy, impactful content creation, and developing data-driven, AI-powered solutions that enhance online visibility and engagement. With a strong foundation in natural language processing and emerging AI technologies, Joydeep is known for simplifying complex concepts into clear, actionable insights.

Joydeep Dey is a seasoned SEO Executive, Content Writer, and AI expert with over 2½ years of experience in digital marketing and artificial intelligence. He specializes in SEO strategy, impactful content creation, and developing data-driven, AI-powered solutions that enhance online visibility and engagement. With a strong foundation in natural language processing and emerging AI technologies, Joydeep is known for simplifying complex concepts into clear, actionable insights.

About the Reviewer

Sanyukta Deb is an accomplished Content Writer and Digital Marketing Strategist with extensive expertise in content strategy, SEO, and audience engagement. She specializes in building strong brand visibility through data-driven campaigns and impactful, value-added researched content. With a passion for creativity and innovation, she blends strategic thinking with design and communication to craft meaningful digital experiences. Over the years, she has contributed cross-functional marketing projects, driving measurable impact and audience engagement.

Sanyukta Deb is an accomplished Content Writer and Digital Marketing Strategist with extensive expertise in content strategy, SEO, and audience engagement. She specializes in building strong brand visibility through data-driven campaigns and impactful, value-added researched content. With a passion for creativity and innovation, she blends strategic thinking with design and communication to craft meaningful digital experiences. Over the years, she has contributed cross-functional marketing projects, driving measurable impact and audience engagement.

Add Comment