How ABB, Rockwell, and Honeywell Are Transforming Industrial Operations with Next-Gen DCS Solutions

Published: 2025-11-13

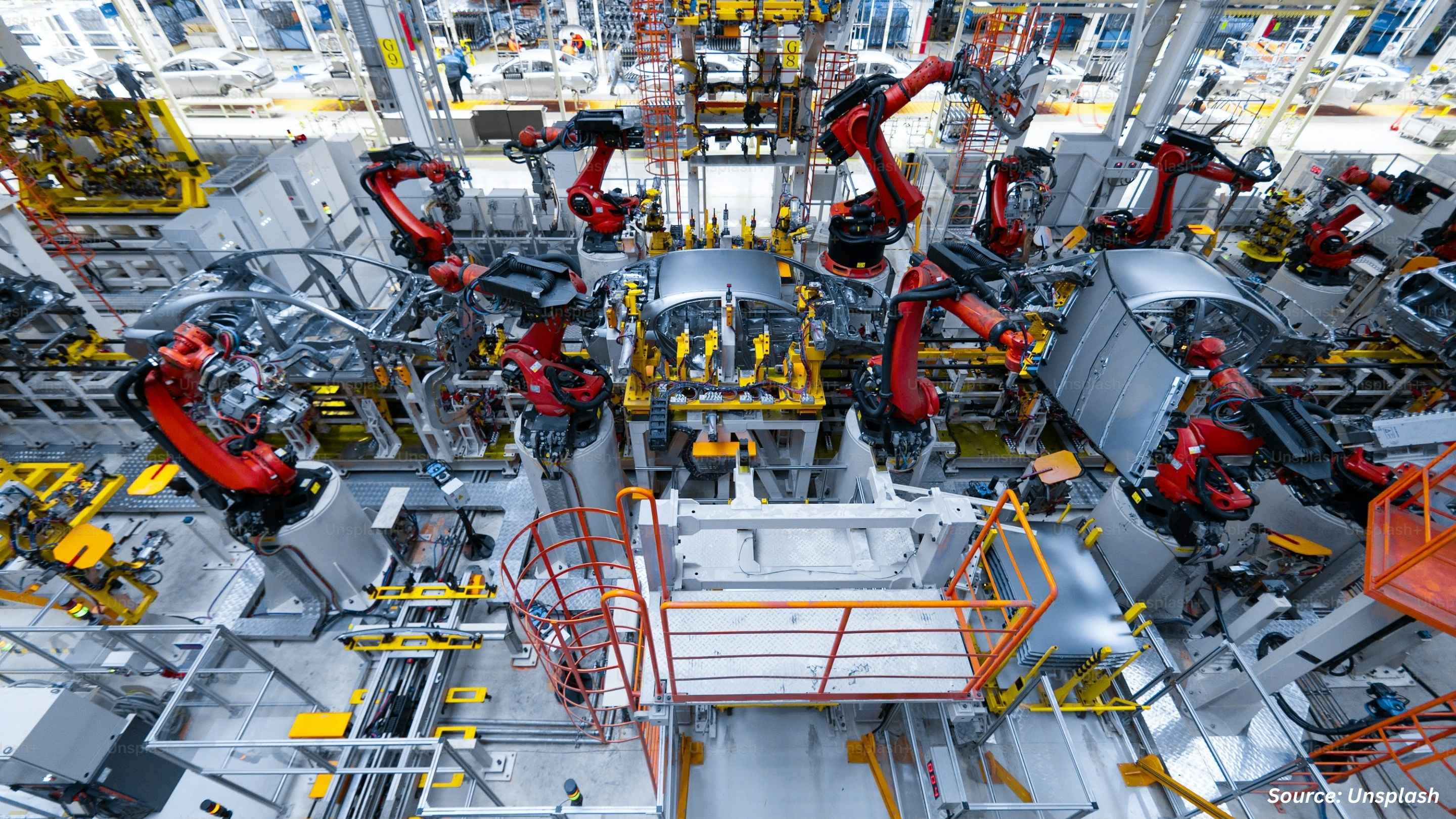

As per NMSC analysis, the Australia distributed control system industry is set to maintain strong growth momentum, with the market size expected to reach around USD 592.8 million by 2030, marking a solid CAGR of 6.6%. Valued at USD 387.5 million in 2024, the Australia distributed control system market is projected to rise to USD 430.7 million by 2025. The Australian distributed control system (DCS) market is experiencing a significant transformation, driven by the rapid adoption of industrial automation and the integration of advanced technologies. Once primarily limited to heavy industries such as oil, gas, and mining, DCS solutions are now being deployed across a diverse range of sectors, including manufacturing, energy, and utilities. The growing emphasis on efficiency, real-time data analytics, and predictive maintenance is pushing companies to adopt more flexible and intelligent control systems. Global and regional players are competing by offering innovative, scalable, and AI-enabled DCS platforms that can adapt to the unique needs of Australian industries. This evolution is reshaping operational processes, improving safety, and enabling smarter, more connected industrial environments, positioning Australia as a hub for modern industrial automation.

Australia Distributed Control System Market Overview

The Australian distributed control system (DCS) market is likewise being reshaped by many of the same forces driving robotics globally: as industries move toward smarter, more connected, and resilient operations, DCS platforms are evolving beyond traditional supervisory and control roles into more intelligent, adaptive infrastructural components. Systems are being designed with built-in AI and analytics for predictive maintenance, cloud-based monitoring, and integration with IoT devices. The push toward smart factories and Industry 4.0 is prompting tighter convergence of operational technology (OT) and information technology (IT), so that DCS solutions can offer real-time visibility, dynamic optimisation, and interoperability across plants and corporate systems. At the same time, Australia’s energy transition particularly grid modernisation and renewable power generation requires DCS platforms to be more flexible, reliable, and capable of coping with variable loads and distributed generation. In sum, DCS in Australia is rapidly entering a stage where intelligence, adaptability, connectivity, and scalability are as much at the core of value as stability and control.

Furthermore, the Australian distributed control system (DCS) market is witnessing growing demand for modular, customizable, and industry-specific control solutions across sectors such as mining, energy, manufacturing, and utilities. As operations become more complex and interconnected, industries are seeking DCS platforms that can seamlessly integrate with enterprise systems, production networks, and emerging digital infrastructure. This need for interoperability is driving innovation in scalable and flexible control architectures that support both centralized and decentralized operations. At the same time, companies are prioritizing sustainability, operational safety, and efficiency through energy-optimized process controls, low-maintenance designs, and AI-enabled monitoring tools that improve reliability while lowering costs. With the rise of digital transformation, renewable energy integration, and skilled workforce shortages, DCS technologies are becoming essential enablers of agile, intelligent, and future-ready industrial strategies, solidifying their position at the core of Australia’s evolving automation landscape.

Several major companies dominating the Australian distributed control system (DCS) market include ABB Ltd., Rockwell Automation Inc., Honeywell International Inc., Siemens AG, and Mitsubishi Electric Corporation. These industry leaders are at the forefront of driving automation innovation across Australia’s key industrial sectors by integrating advanced control technologies with AI, cloud connectivity, and intuitive engineering interfaces. Through the incorporation of predictive analytics, IIoT-enabled services, and flexible, modular DCS architectures, these companies are enabling industries to achieve higher uptime, streamline complex processes, and scale operations more efficiently. Their investments in sustainable automation solutions, energy-optimized process controls, and workforce development programs are strengthening Australia’s industrial capabilities while supporting the nation’s shift toward smarter, more resilient infrastructure. Additionally, their strategic collaborations with local system integrators, utilities, and manufacturers are fostering the deployment of scalable, interoperable control systems that enhance productivity, improve operational visibility, and accelerate digital transformation. By delivering intelligent, secure, and future-ready control solutions, these companies are positioning themselves as key enablers of Australia’s evolving industrial landscape.

For the In-depth Analysis of Australia DCS Industry, you can Reach out to us at: Request for a Sample PDF Report

Highlights of Abb Ltd.

ABB Ltd., headquartered in Zurich, Switzerland, is a global leader in electrification, automation, and digital technologies. The company plays a significant role in the Australian distributed control system (DCS) market by delivering advanced process automation solutions tailored to industries such as energy, mining, utilities, and manufacturing. ABB’s DCS offerings enhance operational efficiency, reliability, and flexibility, enabling organizations to optimize complex processes through intelligent control and real-time data insights. As Australia continues to accelerate its industrial automation and digital transformation efforts, the demand for ABB’s scalable and integrated DCS platforms is rising, strengthening the company’s presence and competitive position in the region’s evolving automation landscape.

In 2024, ABB Australia introduced the upgraded ABB Ability System 800xA DCS Version 6.2, reinforcing its presence in the Australian Distributed Control System market. This latest version reflects the growing demand in Australia for advanced, scalable, and integrated control solutions that enhance operational efficiency, improve process reliability, and support the digital transformation of industries such as energy, mining, and manufacturing. By offering improved connectivity, real-time analytics, and flexible integration capabilities, ABBs updated DCS platform addresses the evolving needs of Australian industries seeking smarter, more agile automation systems.

Highlights of Rockwell Automation

Rockwell Automation Inc., headquartered in Milwaukee, Wisconsin, is a global leader in industrial automation and digital transformation. The company provides integrated control systems, industrial software, and connected services across sectors such as manufacturing, energy, and utilities. Within the Australian distributed control system (DCS) market, the increasing adoption of advanced automation solutions is prompting industries to enhance efficiency, reliability, and process control. Rockwell Automation leverages its expertise in DCS technologies to meet these demands, delivering flexible, scalable, and innovative solutions that support the modernization and digital transformation of Australian industrial operations.

In 2025, Rockwell Automation collaborated with Encore Tissue, a prominent Australian manufacturer, to modernize the control systems at its Victorian facility. Encore Tissue implemented Rockwell’s PlantPAx distributed control system (DCS) to replace its legacy setup, aiming to improve operational efficiency and reliability. The PlantPAx system delivered a fully integrated solution, combining DCS capabilities with safety controllers and drive systems, which streamlined future upgrades and ensured smoother operations. This project highlights Rockwell Automation’s role in advancing the Australian Distributed Control System market, demonstrating its commitment to providing innovative automation solutions that strengthen industrial performance nationwide.

Highlights of Emerson Electric Co.

Emerson Electric Co., headquartered in St. Louis, Missouri, is a leading global technology and engineering company focused on automation solutions, process control, and industrial software. The company provides a wide range of products and services, including distributed control systems (DCS), control valves, and measurement instruments. Within the Australian distributed control system (DCS) market, Emerson is a key contributor, delivering advanced automation technologies that help industries improve efficiency, reliability, and operational performance. The increasing adoption of sophisticated control systems in Australia aligns with Emerson’s strategy to support the country’s industrial modernization and digital transformation initiatives.

In 2024, Emerson was selected by Australia-based H2 Hauler to provide a comprehensive hydrogen mobility business management system, incorporating its DeltaV PK Controller, fire and gas systems, valves, actuators, regulators, and a secure cloud-based platform. The automation solution manages loading and monitoring systems, custody transfer, and trailer asset tracking, enabling safe, efficient, and remotely controlled hydrogen storage and distribution operations. This project highlights Emerson’s role in the Australian distributed control system (DCS) market, demonstrating how advanced DCS technologies are supporting the safe, reliable, and digitally integrated management of emerging energy infrastructure in Australia.

Highlights of Honeywell International Inc

Honeywell International Inc., headquartered in Charlotte, North Carolina, is a global leader in technology and manufacturing, with expertise spanning aerospace, building technologies, performance materials, and industrial automation. The company provides a comprehensive portfolio of products and solutions, including advanced control systems, sensors, and industrial software. Within the Australian distributed control system (DCS) market, Honeywell plays a key role by delivering integrated automation solutions that help industries improve efficiency, reliability, and process optimization. The increasing demand for sophisticated control systems in Australia aligns with Honeywell’s strategic focus on supporting the country’s industrial modernization and digital transformation initiatives.

In 2025, Honeywell announced that it will provide its Experion PKS distributed control system, Universal Operation Controllers, advanced remote-control, and safety solutions with enhanced cybersecurity for Iluka Resources’ first rare-earths refinery in Eneabba, Australia. This project, supported by the Australian Government, highlights the critical role of integrated automation and real-time data insights in the country’s industrial sector. As part of the Australian distributed control system (DCS) market, Honeywell’s solutions will enhance operational efficiency, safety, and process optimization at the refinery, reinforcing the company’s position in Australia’s growing automation landscape and supporting the production of essential rare-earth materials for defense, electrification, and sustainable energy applications.

Highlights of Siemens AG

Siemens AG, headquartered in Munich, Germany, is a leading global technology company specializing in electrification, automation, and digitalization. The company provides a wide array of solutions, including distributed control systems, industrial software, and smart infrastructure technologies. Within the Australian distributed control system (DCS) market, Siemens is a key player, delivering advanced automation solutions that help industries improve efficiency, reliability, and process optimization. The increasing adoption of sophisticated control systems in Australia supports Siemens’ strategic goal of driving industrial innovation and digital transformation across the country’s energy, manufacturing, and utilities sectors.

In 2024, Siemens introduced Gridscale X, an advanced grid management platform aimed at enabling autonomous operations and driving digital transformation for Australian grid operators. This initiative highlights Siemens’ active role in the Australian distributed control system (DCS) market, providing innovative technologies that improve energy distribution, operational efficiency, and system resilience. By deploying Gridscale X, Siemens is addressing the growing demand for intelligent, integrated control solutions in Australia, strengthening its position in the DCS market and supporting the country’s shift toward more sustainable, reliable, and digitally optimized energy and industrial infrastructure.

Summary of Australia Distributed Control System Market

The Australian distributed control system (DCS) market is undergoing significant transformation, driven by the adoption of Industry 4.0 technologies, the need for improved operational efficiency, and the integration of advanced automation across key sectors including energy, mining, manufacturing, and utilities. DCS solutions, once primarily used in traditional heavy process industries, are now critical across a broader range of applications, offering intelligent, scalable, and connected platforms that enhance reliability, safety, and productivity. Growing digitalization, smart factory initiatives, and renewable energy integration are accelerating market adoption in Australia.

Global and regional automation leaders, such as ABB, Rockwell Automation, Siemens, Honeywell, Mitsubishi Electric, and Emerson are driving this evolution by embedding AI, predictive maintenance, cloud connectivity, IoT integration, and cybersecurity into their DCS offerings. Industry projects, including Honeywell’s Experion PKS deployment for Iluka Resources and Emerson’s DeltaV system for H2 Hauler, highlight the practical impact of these technologies on operational efficiency, safety, and process optimization. Sustainability, regulatory compliance, and energy-efficiency objectives are further shaping the market, making DCS solutions essential for Australia’s industrial modernization, digital transformation, and resilient operational strategies.

About the Author

Bidhudhyoti Nag is a seasoned researcher with over two years of experience, specializing in various industry verticals such as the travel accommodation market, HVAC market and construction electronics. With a strong passion for writing, she views blogging as a valuable platform to share her industry insights and expertise. Outside of tracking market trends and developments, Bidhudhyoti is interested in sports, travelling, and exploring new experiences.

Bidhudhyoti Nag is a seasoned researcher with over two years of experience, specializing in various industry verticals such as the travel accommodation market, HVAC market and construction electronics. With a strong passion for writing, she views blogging as a valuable platform to share her industry insights and expertise. Outside of tracking market trends and developments, Bidhudhyoti is interested in sports, travelling, and exploring new experiences.

About the Reviewer

Sikha Haritwal is a researcher with more than 5 years of experience. She has been keeping a close eye on several industry verticals, including construction & manufacturing, personal care products, and consumer electronics. She has avid interest in writing news articles and hopes to use blog as a platform to share her knowledge with others.

Sikha Haritwal is a researcher with more than 5 years of experience. She has been keeping a close eye on several industry verticals, including construction & manufacturing, personal care products, and consumer electronics. She has avid interest in writing news articles and hopes to use blog as a platform to share her knowledge with others.

Add Comment