How is the Manufacturing Execution System (MES) Market Trending in 2025?

Published: 2025-11-20

Manufacturing Execution Systems (MES) are entering a transformative phase in 2025 as vendors shift toward cloud-ready, modular, and sector-specific solutions. This evolution is driven by manufacturers seeking faster deployments, lower on-site IT burdens, and improved compliance across regulated and process-heavy industries. This blog draws exclusively from the two primary sources you provided Tietoevry (2025) and Rockwell Automation (2025).

What Cloud Transformations are Reshaping the MES Market? — Cloud and MES

In June 2025, Tietoevry announced that its TIPS All-in-One MES has entered a new era through a Software as a Service (SaaS) model delivered on the Microsoft Azure public cloud. This marks a significant shift for industries such as pulp, paper, board, nonwoven, and tissue, where MES deployments have historically relied on heavy, on premises infrastructure. The SaaS model reduces on site IT workload, simplifies maintenance, and enables faster implementation cycles. Tietoevry highlights that Microsoft Azure’s global scale and built in cybersecurity capabilities enhance resilience, offering enterprise grade security supported by more than 3,500 cybersecurity experts globally.

Rockwell Automation’s FactoryTalk PharmaSuite 12.00, introduced in May 2025, reinforces this cloud-aligned direction. While it can still be deployed on premises or in hybrid models, it has been redesigned to be cloud ready and capable of running within Kubernetes environments using Linux containers. This infrastructure shift provides major benefits: faster provisioning, improved reliability, and more consistent lifecycle management across regulated environments.

Why are Manufacturers Accelerating Adoption of Cloud-Enabled MES? - Drivers for Cloud MES Adoption

Cloud capable MES is becoming more attractive as manufacturers worldwide pursue modernization strategies that balance cost efficiency with operational resilience. Tietoevry emphasizes that Azure-enabled MES reduces the total cost of ownership by lowering the need for on-site servers, ongoing maintenance, and local IT staffing. The company cites Gartner data indicating that public cloud workloads may experience up to 60% fewer security incidents compared to traditional data centers—an important point for risk averse industries.

For highly regulated sectors such as pharmaceuticals, the move toward cloud and modular MES architectures is equally strategic. Rockwell notes that life sciences companies require validated environments with strong data integrity, audit trails, and cybersecurity layers. Cloud aligned MES solutions can support global rollouts, reduce reliance on rigid legacy installations, and streamline upgrades and validations.

How are MES Vendors Supporting Regulated Industries and Compliance Requirements? - MES for Regulated Manufacturing

Regulated industries demand higher levels of traceability, data integrity, and cybersecurity. Rockwell Automation positions FactoryTalk PharmaSuite 12.00 explicitly for pharmaceutical and biopharmaceutical production environments, where validation cycles, compliance audits, and data governance standards are stringent. The release focuses on enhanced cybersecurity features and architectures designed to simplify validation, making it easier for manufacturers to meet global regulatory requirements.

Similarly, Tietoevry ensures that its TIPS All in One MES addresses compliance needs for pulp and paper industries. Its new Azure-based model ensures secure data handling, streamlined IT governance, and industry specific functionalities that support the sector’s quality and production standards.

What Technical Trends are Shaping MES Design and Deployment In 2025? - Containers, Modularity, and Saas

Several technical trends stand out as defining characteristics of the 2025 MES Market:

1. Containerization and Kubernetes Orchestration

Rockwell’s PharmaSuite 12.00 now runs in Linux containers orchestrated through Kubernetes. This represents a major shift from traditional monolithic MES deployments, enabling:

-

Faster provisioning

-

More predictable scaling

-

Simplified maintenance across distributed manufacturing plants

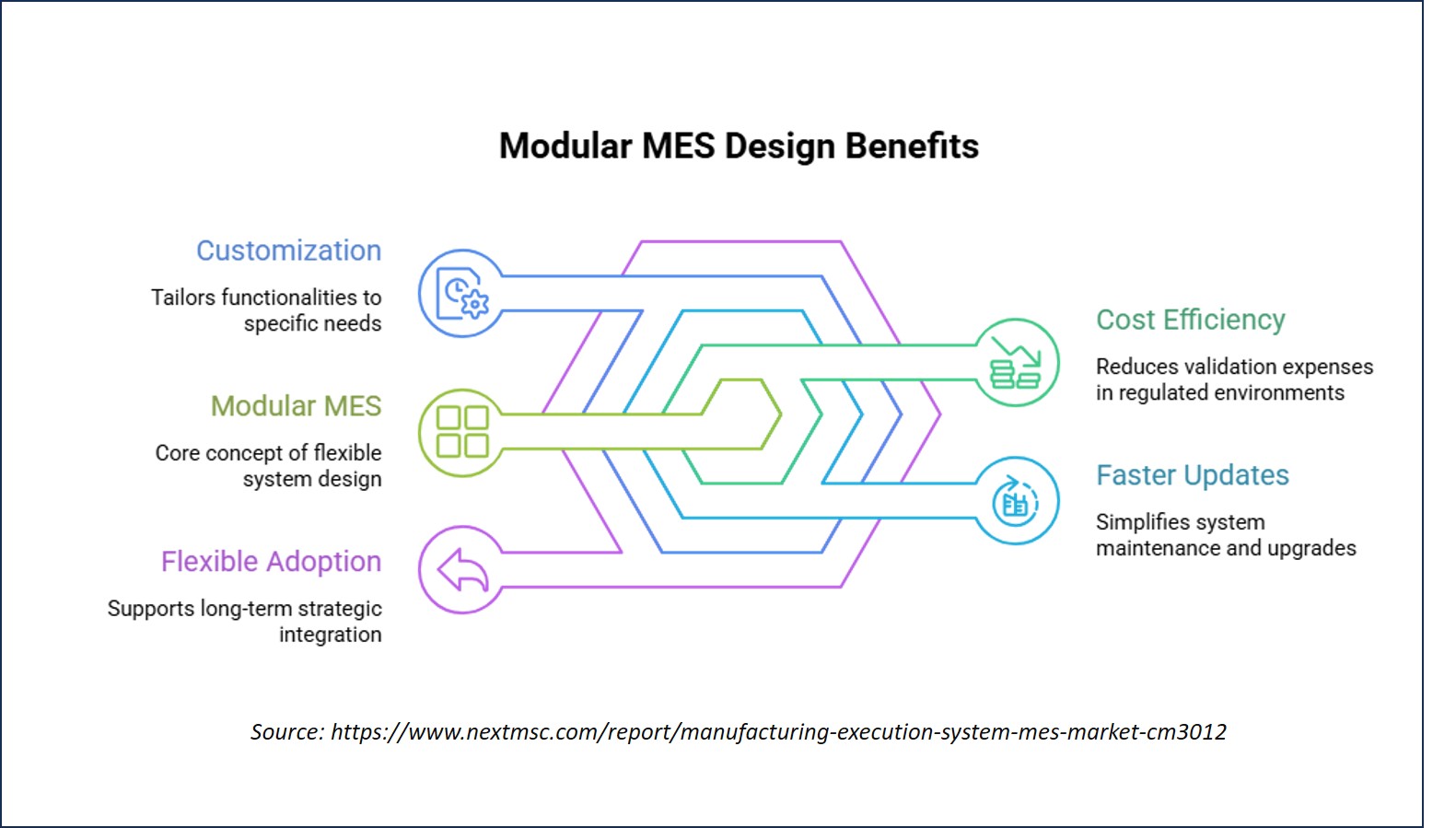

2. Modular Architectures

Modular MES designs allow manufacturers to deploy only the functionalities they require particularly valuable in regulated spaces, where validating entire systems can be costly. Modular architectures support faster updates, easier customization, and more flexible long term adoption strategies.

3. Saas MES Delivered Through Public Cloud Platforms

Tietoevry’s Azure hosted MES demonstrates a strong move toward SaaS delivery, which centralizes updates, reduces maintenance workload, and increases accessibility across geographically distributed operations.

How do these MES Advancements Impact Cost, Security, and Time-to-Value? - Business Implications

The shift toward cloud-ready and modular MES directly influences business performance. Tietoevry notes that Azure-based MES significantly lowers operational costs by reducing physical infrastructure and enabling remote administration. Manufacturers also gain access to Azure’s enterprise-grade security features and global availability zones.

Rockwell emphasizes operational efficiency as a major benefit, noting that containerized and modular MES solutions yield faster deployment cycles, consistent environment management, and better scalability. For pharmaceutical manufacturers, this can reduce validation timeframes and accelerate production readiness.

Together, these developments help organizations:

-

Reduce total cost of ownership

-

Strengthen cybersecurity posture

-

Accelerate global MES rollouts

-

Improve agility in regulated or fast-changing production environments

Quick comparison: Tietoevry TIPS All-in-One vs Rockwell FactoryTalk PharmaSuite 12.00

|

Feature |

Tietoevry TIPS All-in-One (June 2025) |

Rockwell FactoryTalk PharmaSuite 12.00 (May 2025) |

|

Main industry focus |

Pulp, paper, board, nonwoven, tissue |

Pharmaceutical and biopharmaceutical manufacturing |

|

Deployment model |

SaaS on Microsoft Azure |

Cloud, hybrid, on‑prem; container-based using Kubernetes |

|

Key benefits |

Lower on-site IT workload, sector-specific compliance |

Enhanced cybersecurity, simplified validation, modularity |

Regulatory Implementation Driving MES Adoption

The implementation of stringent regulations by governmental organizations is accelerating the adoption of Manufacturing Execution Systems (MES) as companies aim to maintain compliance, improve operational efficiency, and enhance product quality. According to insights from Next Move Strategy Consulting, regulatory bodies are increasingly pushing industries toward digitized, transparent, and tightly controlled production environments.

A notable example is the 2024 initiative by the UN Environmental Programme (UNEP), whose executive body adopted a global strategy focused on redefining waste and advancing zero waste practices. Such regulatory efforts push manufacturers to adopt advanced MES platforms that provide real time traceability, digital documentation, audit-ready reporting, and better resource management, all essential for meeting new sustainability and compliance standards.

About the Author

Joydeep Dey is a passionate digital explorer driven by creativity, strategy, and learning. He has worked in SEO, content creation, and video editing, combining analytical and creative skills to bring ideas to life. He has explored how AI tools and emerging tech transformed digital storytelling and productivity. Guided by curiosity he believes success lies not just in results but in learning something new every day. He continues to evolve with every project, striving to inspire through innovation and impact. His journey reflects a mindset of progress and purpose.

Joydeep Dey is a passionate digital explorer driven by creativity, strategy, and learning. He has worked in SEO, content creation, and video editing, combining analytical and creative skills to bring ideas to life. He has explored how AI tools and emerging tech transformed digital storytelling and productivity. Guided by curiosity he believes success lies not just in results but in learning something new every day. He continues to evolve with every project, striving to inspire through innovation and impact. His journey reflects a mindset of progress and purpose.

About the Reviewer

Sanyukta Deb is an accomplished Content Writer and Digital Marketing Strategist with extensive expertise in content strategy, SEO, and audience engagement. She specializes in building strong brand visibility through data-driven campaigns and impactful, value-added researched content. With a passion for creativity and innovation, she blends strategic thinking with design and communication to craft meaningful digital experiences. Over the years, she has contributed cross-functional marketing projects, driving measurable impact and audience engagement.

Sanyukta Deb is an accomplished Content Writer and Digital Marketing Strategist with extensive expertise in content strategy, SEO, and audience engagement. She specializes in building strong brand visibility through data-driven campaigns and impactful, value-added researched content. With a passion for creativity and innovation, she blends strategic thinking with design and communication to craft meaningful digital experiences. Over the years, she has contributed cross-functional marketing projects, driving measurable impact and audience engagement.

Add Comment