Top 5 Trends Shaping the Brazil Intralogistics Software Industry

Published: 2025-09-10

Intralogistics software refers to the digital backbone that coordinates, manages, and optimizes internal logistics processes within facilities such as factories, warehouses, and distribution centres. These systems control and automate material handling, inventory management, and goods flow within organizations.

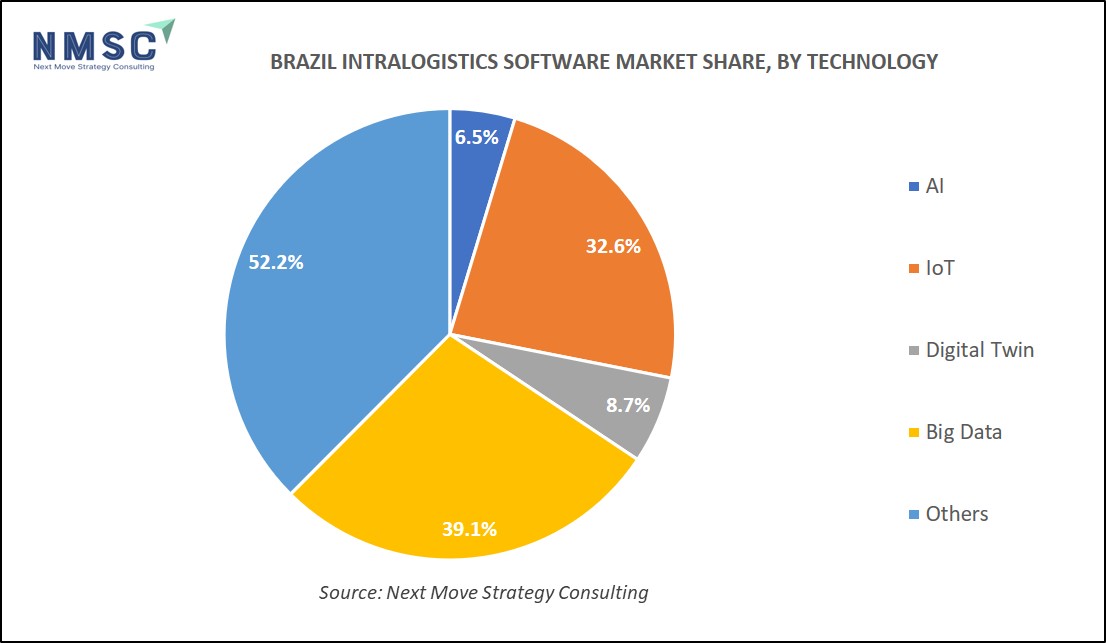

As the era of Industry 4.0 advances, intralogistics software is becoming a cornerstone in sectors where speed, precision, and automation are essential, particularly in the automotive industry. According to Next Move Strategy Consulting, the Brazil Intralogistics Software Market is projected to continue its growth trajectory, reaching USD 270.35 billion by 2030, with a CAGR of 12.9% from 2025 to 2030.

Curious about the Brazil Intralogistics Software Market? Grab your FREE Sample

This blog explores how Brazil’s rapidly growing automotive industry is driving a major transformation in the intralogistics software market. With vehicle production surging and OEMs expanding local operations, there's an urgent demand for next-generation intralogistics solutions powered by AI, IoT, robotics, and digital twins.

The blog explains how these advanced technologies are enabling real-time visibility, predictive planning, and automation across manufacturing facilities. It also highlights how these innovations are not only enhancing operational efficiency in automotive plants but are extending into other sectors like healthcare and e-commerce. In the context of Brazil, a country experiencing significant growth in its automotive sector, the impact of such technology-driven intralogistics systems is increasingly transformative.

Top 5 Game-Changing Technologies Revolutionizing Brazil’s Intralogistics in 2025

AI & Machine Learning – AI and Machine Learning (ML) are transforming Brazil’s intralogistics by enabling intelligent decision-making and predictive capabilities. Companies like Blue Yonder, its Luminate leverage AI delivers end-to-end visibility and real-time responsiveness across the supply chain. Its advanced demand forecasting models analyse historical and real-time data to predict customer needs with high accuracy.

Anomaly detection tools automatically flag disruptions—such as delays, stockouts, or demand spikes—allowing businesses to act before issues escalate. Additionally, the automated replenishment feature ensures optimal stock levels by dynamically adjusting inventory based on demand shifts. This results in reduced downtime, enhanced efficiency, and greater supply chain resilience.

IoT & RFID Tracking – IoT and RFID tracking technologies are revolutionizing intralogistics by offering unparalleled visibility into the movement of goods and assets. The company, Inpixon provides RTLS Platform that utilizes technologies like Ultra-Wideband (UWB), RFID, and edge sensors to deliver accurate, real-time location data. Integrated with (WMS) and (MES), it enables seamless coordination across operations.

Beacons and RFID tags continuously transmit critical data—such as exact part location, container weight, and temperature or humidity levels—allowing for precise line-side delivery, optimized storage layouts, and real-time exception handling. This results in improved inventory accuracy, reduced delays, and enhanced operational efficiency.

Cloud & SaaS Orchestration – Cloud and SaaS orchestration is pivotal for harmonizing operations across multiple facilities, especially as Brazil experiences rapid greenfield expansion by OEMs. The company, SnapLogic enables this orchestration through its AI-powered Integration Platform as a Service (iPaaS), which connects cloud and on-premise systems via robust API management and pre-built connectors.

It facilitates real-time data flow between WMS, WES, ERP, and MES platforms, allowing centralized dashboards to deliver a unified view of logistics operations. The platform’s AI-driven automation streamlines data mapping, error handling, and process execution—empowering manufacturers to scale rapidly, reduce integration complexity, and respond swiftly to market changes and production demands.

Big Data - Big data is revolutionizing intralogistics software by enabling smarter, faster, and more efficient decision-making across warehouse and distribution operations. Through real-time data collection from sensors, RFID tags, automated storage systems, and IoT-enabled machinery, big data analytics helps track inventory levels, predict demand patterns, and optimize routing of goods and labor. This not only improves order accuracy and reduces delays but also minimizes operational costs by identifying bottlenecks and underutilized assets.

Moreover, big data enhances predictive maintenance of intralogistics equipment, reducing unplanned downtime. As a result, companies can achieve higher throughput, better resource allocation, and a more responsive supply chain ecosystem.

Digital Twin & Simulation – Digital twin and simulation technologies are transforming intralogistics by enabling predictive planning and real-time optimization. The company, Siemens, provides Logistics Digital Twin, which is a part of the Siemens Digital Enterprise suite, creates a dynamic, virtual replica of warehouse operations and material flow processes. This tool allows planners to simulate layout adjustments, optimize robot paths, and test scheduling scenarios before implementation, minimizing risk and downtime.

By integrating real-time data from sensors, PLCs, and ERP systems, it enables continuous performance monitoring and scenario analysis. This results in data-driven decision-making, enhanced throughput, and agile responses to operational changes—all critical for efficient, scalable intralogistics in modern facilities.

Strategic Moves: How Tech Leaders and OEMs Are Reinventing the Logistics Game

Local and global vendors are rapidly advancing Brazil’s intralogistics landscape, delivering turnkey solutions tailored for the country’s fast-scaling automotive mega-factories. SAP SE and Tecsys are enhancing their warehouse management (WMS) and execution systems (WES) with AI-powered modules aimed at optimizing material flow and operational agility. Valeo’s newly launched anSWer software suite targets both in-vehicle logistics and backend warehouse coordination, streamlining efficiency across the supply chain.

New entrant, like Cobli, logistics tech startup offers plug and play fleet management, vehicle telemetry, route optimization, and real time monitoring APIs. Their telematics platform, well-suited for modular enterprise use, is innovating how Brazilian intralogistics handles mobility and data-driven dispatching.

OEMs are also partnering with logistics-as-a-service specialists. Horizon Auto Logistics entered Brazil in late 2023 to handle specialized vehicle terminal logistics, leveraging internal intralogistics data to refine yard operations and docking efficiency.

Adding to this trend, ECARX’s integration of digital cockpits in Volkswagen Brazil models marks a push toward intelligent, software-defined vehicle ecosystems—bridging intralogistics with end-user traceability and reinforcing the shift to fully connected manufacturing value chains.

Conclusion: Charting the Future of Intralogistics in Brazil

As Brazil’s automotive industry accelerates toward smart manufacturing, the intralogistics software landscape is evolving just as rapidly. Technologies such as AI, IoT, big data, digital twins, and cloud orchestration are no longer optional they are fundamental to ensuring efficiency, agility, and competitiveness in modern supply chains.

Backed by robust innovation from tech leaders and strategic moves by OEMs, Brazil is positioning itself as a hotspot for digital transformation in logistics. The convergence of advanced software and rising industrial demand signals a future where intelligent intralogistics will define operational excellence across multiple sectors.

About the Author

Mayurima Roy is a seasoned researcher with over two years of experience, specializing in various industry verticals such as Pet apparels, recycling market, and consumer electronics. With a strong passion for writing, she views blogging as a valuable platform to share her industry insights and expertise. Outside of tracking market trends and developments, Mayurima enjoys crafting, cooking, and exploring her creativity through photography.

Mayurima Roy is a seasoned researcher with over two years of experience, specializing in various industry verticals such as Pet apparels, recycling market, and consumer electronics. With a strong passion for writing, she views blogging as a valuable platform to share her industry insights and expertise. Outside of tracking market trends and developments, Mayurima enjoys crafting, cooking, and exploring her creativity through photography.

About the Reviewer

Debashree Dey is a skilled Content Writer, PR Specialist, and Assistant Manager with strong expertise in Digital Marketing. She specializes in crafting visibility strategies and delivering impactful, data-driven campaigns. Passionate about creating engaging, audience-focused content, she helps brands strengthen their online presence. Beyond work, she draws inspiration from creative projects and design pursuits.

Debashree Dey is a skilled Content Writer, PR Specialist, and Assistant Manager with strong expertise in Digital Marketing. She specializes in crafting visibility strategies and delivering impactful, data-driven campaigns. Passionate about creating engaging, audience-focused content, she helps brands strengthen their online presence. Beyond work, she draws inspiration from creative projects and design pursuits.

Add Comment